[Function Description]

The CNC router with disc tool changer and pneumatic drill is specially developed for whole-house customized panel furniture. It has all the functions of disc tool changer ATC CNC router and is equipped with a 5+4 pneumatic drill package to facilitate drilling of panels, which is more suitable for panel furniture production.

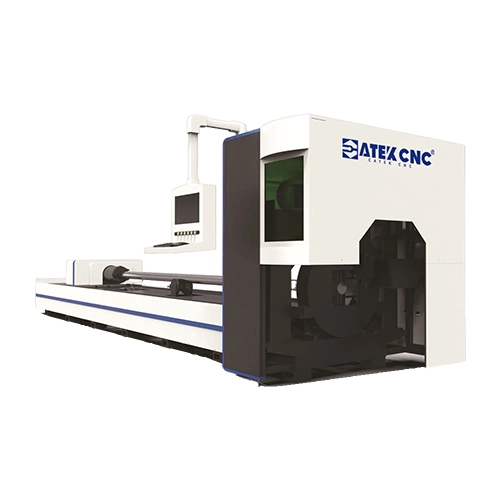

Overview of Disc ATC CNC Router With Pneumatic Drill

The CNC router with disc tool changer and pneumatic drill is a CNC router specially developed for customized panel furniture for the whole house. This engraving machine uses a 9KW automatic tool change spindle and a 12-disc tool changer magazine. It can automatically change tools when processing products with different processing technologies. At the same time, it uses a 5+4 pneumatic drill pack to quickly punch holes in the board, saving drilling time and improving efficiency. It is more suitable for panel furniture production, MDF and other board cutting, and is used for processing various types of board cutting, drilling, grooving, milling, etc. It is suitable for various furniture production factories, which can greatly improve production efficiency, making complex work easier to complete, and the processed products are more standardized, more refined in appearance, and improve product strength. In addition, the machine is easy to operate and the CNC program is integrated. You only need to copy the drawings to the machine and the machine can start processing. Whether you are a CNC expert or a novice, you can easily master the operation of the CNC router and process it.

Advantages of Disc ATC CNC Router With Pneumatic Drill

Using 9KW HQD fully automatic tool-changing air-cooled spindle, equipped with ISO30 toolholder and ER32 toolholder, it can realize fully automatic switching of 8/12/16 tools, and can clamp toolholders within 20mm at most, supporting more tools.

Using an 11KW high-power water ring vacuum pump, a 6-zone 24-hole vacuum adsorption table and a 4+2 positioning cylinder, the plate can be quickly positioned. A vortex air-cooled vacuum pump or a rotary vane vacuum pump can be selected.

The fully automatic tool setting instrument can realize fully automatic one-button positioning and tool setting regardless of the length and size of the tool used, making processing more convenient.

Use a high-power double-barrel bag vacuum cleaner and a follow-up vacuum tube to vacuum while processing, which can achieve zero dust pollution on the machine and is more environmentally friendly.

Using the 5+4 pneumatic drill package, various types of holes can be processed with faster drilling speed, faster effect and higher efficiency. The optional side hole drill package can be used to drill holes on the side of the plate.

It uses Taiwan LNC four-axis CNC router dedicated system, with complete expansion functions and user-friendly operation interface. It can support various advanced functions, including fully automatic loading and unloading functions, saw blade cutting function, pressure roller, 5+4 row drill package and other functions.

Disc ATC CNC Router With Pneumatic Drill Technical Parameters

| Model | CK-1325-AD |

| XYZ Work Schedule | 1300*2500*200mm(customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, reinforced steel beams |

| Lathe Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Spindle | HQD 9KW high power air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/m |

| Driving Mode | High torque 1.5KW pure servo motor drive * 4 (Z axis uses brake motor) |

| Reducer | Japan Shimpo reducer |

| Tool Change Magazine | 8/12/16 disc tool magazine |

| Table | Double-layer vacuum table with 6 partitions and 24 wells |

| Vacuum Pump | 11KW water ring vacuum pump |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan high precision 30 linear square rail/30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW Double-barrel Bag Vacuum Cleaner |

| Drill | 5+4 Pneumatic Drilling Kit |

| Control System | Taiwan LNC cutting machine dedicated control system |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, JDpaint, etc. |

| Engraving Instructions | Standard G code |

| Positioning | 4+2 Positioning Cylinder |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Processing Speed | 28000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 3000kg |

| Expanded Size | 3900*2150*2100mm |

Detailed Introduction of Disc ATC CNC Router With Pneumatic Drill

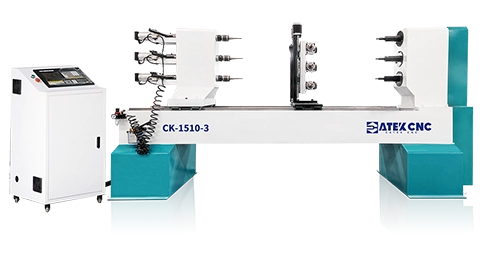

Automatic tool changer

5+4 Pneumatic Drilling Kit

It use HQD supercharged CNC drill, which is high quality, low temperature, low noise, 3200r/m, can hold 9 drill bits, and perform batch hole opening work on wood. We use high-quality two-position three-way direct-acting solenoid valves, which are sensitive to reversing and can start at zero pressure/low vacuum. The valve group uses double-row solenoid valve integrated wiring, which greatly reduces the single sub-space in the length direction. The single valve of the integrated valve group uses a pin-type coil, and the plate-type with sealing gasket is installed for easy maintenance.

The following are the processable products of Disc ATC CNC Router With Pneumatic Drill for your reference

How to use a CNC router with a disc automatic tool changer and pneumatic drill?

When the machine is shipped, we will bring you a USB flash drive with a teaching video and design drawing software. You can refer to the teaching video for learning.

We can also provide you with machine drawing software after you purchase the machine, so you can learn in advance.

After receiving the machine, we can provide you with remote online guidance or remote training through video chat.

If you need, we can provide door-to-door teaching services.

| Model | CK-1325-AD |

| XYZ Work Schedule | 1300*2500*200mm(customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, reinforced steel beams |

| Lathe Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Spindle | HQD 9KW high power air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/m |

| Driving Mode | High torque 1.5KW pure servo motor drive * 4 (Z axis uses brake motor) |

| Reducer | Japan Shimpo reducer |

| Tool Change Magazine | 8/12/16 disc tool magazine |

| Table | Double-layer vacuum table with 6 partitions and 24 wells |

| Vacuum Pump | 11KW water ring vacuum pump |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan high precision 30 linear square rail/30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW Double-barrel Bag Vacuum Cleaner |

| Drill | 5+4 Pneumatic Drilling Kit |

| Control System | Taiwan LNC cutting machine dedicated control system |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, JDpaint, etc. |

| Engraving Instructions | Standard G code |

| Positioning | 4+2 Positioning Cylinder |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Pocessing Speed | 28000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 3000kg |

| Expanded Size | 3900*2150*2100mm |

REVIEWS

Let more people know what you share.