[Function Description]

Plasma cutter is a metal cutting machine. When cutting metal of small thickness, the cutting speed is extremely fast, and the cutting surface is smooth, the thermal deformation is small, and there is almost no heat-affected zone.

Overview of 5x10-Foot High Performance Plasma Cutter

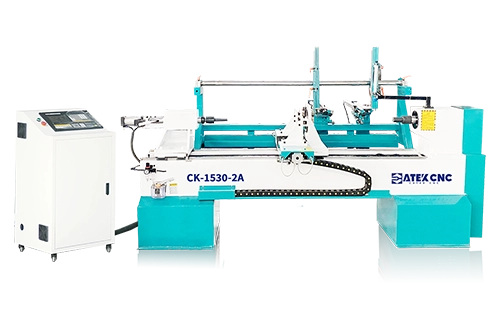

The 1530 CNC plasma cutter is a highly efficient automated equipment for cutting metal sheets. In production and processing, different power plasma power supplies are used according to different maximum cutting thicknesses, which is suitable for different industrial needs. This machine is capable of longitudinal and transverse straight-line cutting and arc-curve cutting in any orientation. It uses a bilateral motor drive and high-precision helical rack/linear guide/slider to achieve high-precision processing and fast operation. CNC plasma cutting is configured with automatic arc starting through the CNC system, with stable performance, supporting standard G-code path files generated by a variety of software, wide compatibility, and using a light beam and gantry structure design. It has a light weight and small motion inertia, making it more suitable for industrial production and processing, and suitable for batch production and processing in various processing workshops.

Advantages of 5x10-Foot High Performance Plasma Cutter

The processing size of the 5*10-foot high-performance CNC plasma cutter is 1500mm on the X axis and 3000mm on the Y axis. Through high-precision control, X, Y, and Z have a repeat positioning accuracy of ±0.01mm. The maximum cutting speed can reach 12000mm/min. It supports flame cutting and plasma cutting and has a wide cutting range.

Mini CNC Router Technical Parameters

Application Scope of 5x10-Foot High Performance Plasma Cutter

Applicable Materials:

Iron, stainless steel, carbon steel, alloy steel, aluminum plate, copper, titanium alloy, magnesium, nickel, ferrochrome and other metal plates.

Applicable Industries:

Automobile manufacturing

Shipbuilding

Fan manufacturing

Kitchen cabinets

Chassis and cabinets

Pressure vessels

Steel structure processing

Steel plate cutting and blanking

Advertising cutting

Sheet metal processing

Engineering machinery

Agricultural machinery and other machinery

Boiler manufacturing

Metal doors and windows

Metal panels and base plates for advertising 3D luminous characters and grooved characters

Other industries

5x10-Foot High Performance Plasma Cutter Technical Parameters

| Model | CK-1530-P |

| Work Area | 1500mm*3000mm |

| Power | 63A/120A/160A/200A/300A/400A |

| Gas | Oxygen |

| Application | Metal fabrications |

| Guideway | Taiwan Hiwin square guide rail + X Y rack and Z ball screw |

| Relay Accessories | Schneider |

| Torch Height Controller | Standard high sensitivity arc voltage device |

| Driving System | Leadshine motor and driver |

| Control System | Starfire control system |

| Lubrication System | Electric lubricating oil pot |

| Operating Voltage | 220V/380V 50/60Hz |

| Nesting Software | FASTCAM |

| File Output Mode | USB interface |

| Instruction Format | G code |

| Repeat Positioning Accuracy | ±0.05mm |

| Process Precision | ±0.35mm |

| Maximum Pocessing Speed | 12000mm/min |

| Weight | 1200kg |

| Expanded Size | 3830*2260*1580mm |

Detailed Introduction of 5x10-Foot High Performance Plasma Cutter

Plasma cutting head

CNC plasma cutting head with fast perforation and cutting of metal materials

Knife strip platform

Distributed knife strip platform with good thermal conductivity and without easy to stick

Plasma generator

American Hypertherm/China Huayuan high-quality high-frequency plasma generator

Control system

Starfire control system Support cutting process settings break point positioning and other advanced functions

The following are the processable products of 5x10-Foot High Performance Plasma Cutter

Usage Matters

CNC plasma cutter is an efficient and precise equipment, widely used in metal processing industry. In order to ensure its safe and efficient operation, operators must strictly abide by the following usage matters:

Operator requirements:

The operator must be professionally trained and be able to operate the CNC plasma cutter proficiently.

The operator should understand every component of the equipment and its function, and master the positive and negative directions of the CNC drive axis.

Preparation before starting:

Check the cutting site, remove flammable and explosive items, and ensure that they are away from the jet area.

Check fire-fighting equipment, such as fire hydrants, fire extinguishers, sandboxes and other fire-fighting facilities.

Confirm that the switches and buttons on the panel are flexible and reliable, and check whether the power supply is normal.

Start the equipment:

Open the power lock on the operation panel, press the power button, and power on the CNC plasma cutter.

Connect the dust collector power supply and check whether the indicator light on the control box panel is normal.

CNC performs internal self-diagnosis and press the start processing key after confirming that there is no error message displayed.

Precautions during operation:

Operators should wear welding gloves, hats and other protective equipment.

During the cutting process, if an emergency occurs, the red emergency stop switch should be pressed immediately.

Avoid direct contact with the cutting surface, torch tip or nozzle during cutting.

Cutting parameter setting:

Before cutting, make sure that the set process parameters match the material and thickness of the plate being cut.

After the first piece of workpiece is cut, it must be inspected and qualified before batch cutting can be carried out.

Daily care and maintenance:

After work every day, clean the dust and metal residue on the cutting machine, especially the area around the electrode and nozzle.

Regularly lubricate the mechanical parts of the cutter, such as guide rails, bearings, etc.

Clean the machine thoroughly every week, clean the horizontal and vertical guide rails, transmission gear racks, and add lubricating

Shutdown and storage:

After finishing the work, close all the gas valves of the cutter and release the remaining gas in the air pipe.

Safety precautions:

The cutter housing should be firmly grounded, and ensure that the grounding bolt of the power supply is properly grounded to prevent electric shock.

Before replacing the welding torch and replacing parts, the power supply must be turned off.

By strictly complying with the above usage precautions, the safe operation of the CNC plasma cutter can be effectively guaranteed and its service life can be extended.

| Model | CK-1530-P |

| Work Area | 1500mm*3000mm |

| Power | 63A/120A/160A/200A/300A/400A |

| Gas | Oxygen |

| Application | Metal fabrications |

| Guideway | Taiwan Hiwin square guide rail + X Y rack and Z ball screw |

| Relay Accessories | Schneider |

| Torch Height Controller | Standard high sensitivity arc voltage device |

| Driving System | Leadshine motor and driver |

| Control System | Starfire control system |

| Lubrication System | Electric lubricating oil pot |

| Operating Voltage | 220V/380V 50/60Hz |

| Nesting Software | FASTCAM |

| File Output Mode | USB interface |

| Instruction Format | G code |

| Repeat Positioning Accuracy | ±0.05mm |

| Process Precision | ±0.35mm |

| Maximum Pocessing Speed | 12000mm/min |

| Weight | 1200kg |

| Expanded Size | 3830*2260*1580mm |

REVIEWS

Let more people know what you share.