[Function Description]

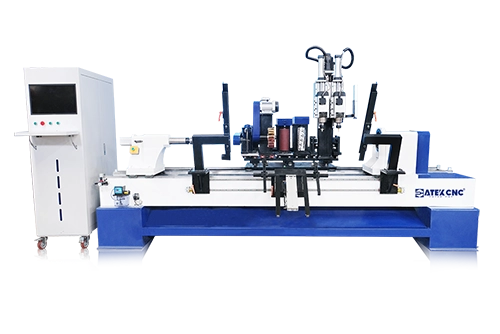

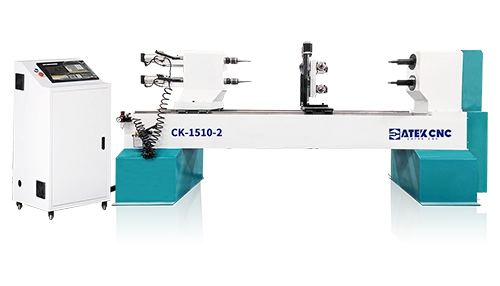

The Multi-Headed 3D CNC Router has multiple heads and can process multiple products at the same time, which can significantly save working time and ensure good consistency of the finished products when producing the same products in large quantities.

Overview of Multi-Headed 3D CNC Router

Multi-headed 3D CNC router are suitable for various scenarios. Personal DIY studios, furniture production factories, small factories, and large production workshops can all use this CNC router. Multi-headed 3D CNC router can be customized according to your requirements. They can process one or more at a time. Personal small studios can choose to use 1-4 processing stations, and larger processing and production factories can choose to use 6-16 processing stations. The more the number, the higher the efficiency. Four-axis 3D engraving can process various complex shapes and can process various materials such as wood, plastic, acrylic, PVC, etc. Whether you are doing personal DIY or using it for factory processing,

multi-headed 3D CNC router can meet your needs and provide more possibilities for your production and manufacturing.

Advantages of Multi-Headed 3D CNC Router

Using multiple high-speed water-cooled variable frequency spindles (the number of spindles can be customized), the speed can reach 24000rpm/min, which can quickly process raw materials, quickly cut, punch, slot, mill, engrave and other functions on the materials, and can process multiple products at a time with higher efficiency. The machine processing size can also be customized to adapt to your raw materials. You only need to use simple computer programming, import the drawings into the machine, and start fully automatic processing, saving labor time and improving efficiency.

Each rotating axis is driven by an independent worm reducer, the speed is stable, and the position is good. At the same time, the fourth axis uses a motor drive. It is linked to rotate with the worm reducer. The angle is accurate. It can be accurate to 0.001 degrees. Caliba or pinch, a hand -shaking or cylinder type at a stitched section, simple and easy to use, convenient on the material.

Support power-off resume, you can resume work after the machine is accidentally powered off.

Rich in functions and easy to expand. After adding appropriate options, the machine can not only perform 3D engraving, but also flat engraving work.

Application Scope of Multi-Headed 3D CNC Router

Applicable Materials:

Wood, PVC, acrylic, plastic, foam, artificial wood, various artificial materials, chemical materials, etc.

Applicable Industries:

Furniture industry: table legs, chair legs, sofa legs, stair railings, Roman columns, European furniture, etc.

Crafts industry: 3D character carving, 3D animal carving, vases, pen holders and other product carving processing.

Daily necessities processing: axe handles, hammer handles, baseball bats, etc.

Multi-Headed 3D CNC Router Technical Parameters

| Model | CK-1020-10S |

| Processing Dimensions | 1000*200*200mm (processing size and quantity can be customized) |

| Lathe Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Gantry | Thickened cast iron gantry, thickened cast iron bracket |

| Spindle | 3.5KW high-speed water-cooled spindle*10 (the number of spindles can be customized) |

| Spindle Speed | 6000-24000r/m |

| Table | Aluminum Alloy T-Slot Table Top |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan Hiwin high precision 25 linear square rail |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Holdable Tool Shank Diameter | 3.175mm,4mm,6mm,12.7mm etc. |

| Control System | UIZHITIANHONG Four-axis DSP handle |

| Lubrication System | Fully automatic oil filling and maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, solidworks UG powermill, etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Pocessing Speed | 18000mm/min |

| Maximum No-Load Running Speed | 25000mm/min |

| Weight | 1800kg |

| Expanded Size | 2600*1900*1650mm |

Detailed Introduction of Multi-Headed 3D CNC Router

Multi-Headed 3D CNC Router with full protective cover

The following are the processable products of Multi-Headed 3D CNC Router

| Model | CK-1020-10S |

| Processing Dimensions | 1000*200*200mm (processing size and quantity can be customized) |

| Lathe Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Gantry | Thickened cast iron gantry, thickened cast iron bracket |

| Spindle | 3.5KW high-speed water-cooled spindle*10 (the number of spindles can be customized) |

| Spindle Speed | 6000-24000r/m |

| Driving Mode | DORNA 1.5KW servo motor drive (Z-axis brake motor) |

| Table | Aluminum Alloy T-Slot Table Top |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan Hiwin high precision 25 linear square rail |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Holdable Tool Shank Diameter | 3.175mm,4mm,6mm,12.7mm etc. |

| Control System | UIZHITIANHONG Four-axis DSP handle |

| Lubrication System | Fully automatic oil filling and maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, solidworks UG powermill, etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Pocessing Speed | 18000mm/min |

| Maximum No-Load Running Speed | 25000mm/min |

| Weight | 1800kg |

| Expanded Size | 2600*1900*1650mm |

REVIEWS

Let more people know what you share.