[Function Description]

CNC vibrating knife cutting machine is a kind of cutting equipment specially used for processing flexible materials. It can cut efficiently and accurately, providing convenient and high-quality solutions for industries such as shoemaking, packaging, and construction.

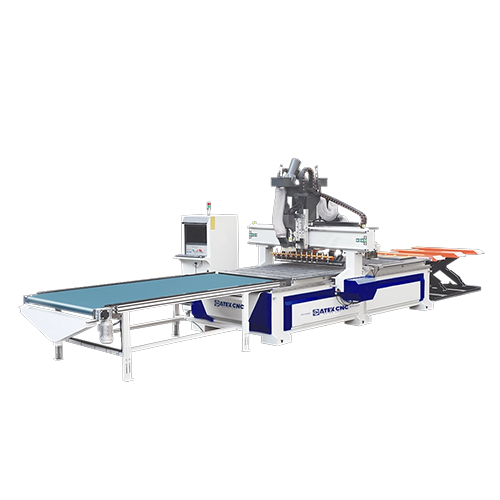

Overview of Automatic CNC Vibrating Knife Cutting Machine

CNC vibration knife cutting machine is a kind of cutting equipment specially used for processing flexible materials. It can cut efficiently and accurately, providing convenient and high-quality solutions for industries such as shoemaking, packaging, and construction.

Advantages of Automatic CNC Vibrating Knife Cutting Machine

Intelligent cutting, no mold required, suitable for a variety of materials, simple operation, fast cutting speed.

Computer data cutting is used to complete cutting, punching and creasing at one time. The cutting process is simple and convenient, no mold is required, the cost is lower, materials are saved and the efficiency is high.

The CNC vibrating knife cutting machine uses advanced cutting technology and automation systems to achieve fast and accurate cutting of various sizes and shapes. The operator can easily control the machine to process by inputting the required cutting parameters and patterns through the computer interface. The CNC system can accurately control the movement and cutting depth of the cutting tool to ensure the consistency of the size and shape of each cut piece.

Introduction of cutting tools for Automatic CNC Vibrating Knife Cutting Machine

Electric vibrating knife: high frequency vibration driven by motor: more suitable for leather, soft glass, foot pads and other airtight and flexible materials

Pneumatic knife: Pneumatic vibration knife is a kind of tool that relies on air vibration. It is suitable for cutting hard, high-density materials such as honeycomb panels, gasket rubber, soles, etc., and thicker EVA materials.

Round knife: This is a special knife more suitable for textile cutting, especially suitable for breathable fabrics, textiles, fur fabrics, etc.

Bevel cutter: Bevel cutter is suitable for V-groove cutting of foam materials, corrugated paper, soft glass and other materials as well as cutting at various angles.

Creasing knife: Creasing knife is used to crease corrugated materials. Different crease tools can produce perfect creasing effects for different materials.

Drag knife: Drag knife cutting tools are used for through-cutting of special materials with high speed and low cost.

CCD camera vision system: suitable for irregular leather cutting, digital printing, embroidery, automatic edge positioning cutting, high precision, saving materials.

Projector: Projector positioning is applied to irregular leather, projection cutting, pattern positioning cutting, etc.

The following are the processable products of Automatic CNC Vibrating Knife Cutting Machine

Furniture industry: fabric sofas, carpet mats, curtains, soft beds, tablecloths, table mats, etc.

Clothing industry: clothing fabric cutting, high-end custom clothing cutting, fur and fur cutting.

Automotive interior: car mats, leather seats, steering wheel covers, car covers, curtains, etc.

Leather shoes and bags: brand bags, wallets, suitcases, all kinds of leather shoes, bags, etc.

Composite materials: carbon fiber, fiber cotton, pearl cotton, fiber cotton, sound insulation cotton, foam board, etc.

Sealing gaskets: graphite, asbestos, non-asbestos, rubber, PTFE, cork, silicone, etc.

Advertising industry: KT board, self-adhesive, color box packaging, advertising light box, etc.

Automatic CNC Vibrating Knife Cutting Machine Technical Parameters

| Model | CK-1610、CK-1625、CK-1825、CK-2125 |

| Processing Dimensions | CK-0610: 1600*1000mm、CK-1625: 1600*2500mm、CK-1825: 1800*2500mm、CK-2125: 2100*2500mm |

| Body Structure | Overall precision welding |

| Gantry | High-strength aviation aluminum integrated gantry structure |

| Feeding Method | Manual feeding/automatic feeding (optional) |

| Driving Mode | Intelligent digital control servo |

| Transmission Mode | Precision rack + linear guide |

| Table | Aviation aluminum vacuum adsorption platform + 4mm thick fiber tablecloth |

| Material Fixing Method | Vacuum adsorption |

| CNC System | Full touch LCD display |

| Transmission Port | USB, network port |

| Fan | 5.5KW/7.5KW/9KW (optional) three-phase AC vortex vacuum adsorption fan |

| Vision Positioning Cutting | Camera, projector (optional) |

| Optional Tools | Vibrating knife, circular knife, pneumatic knife, drag knife, creasing, beveling, punching, etc. (optional) |

| Operating Voltage | AC 220V/380V 50Hz-60Hz |

| Security System | Infrared sensor + emergency stop switch (double protection) |

| Maximum Pocessing Speed | 0-1500mm/s (depending on the material) |

Detailed Introduction of Automatic CNC Vibrating Knife Cutting Machine

The following are the processable products of Automatic CNC Vibrating Knife Cutting Machine

| Model | CK-1610、CK-1625、CK-1825、CK-2125 |

| Processing Dimensions | CK-0610: 1600*1000mm、CK-0625: 1600*2500mm、CK-1825: 1800*2500mm、CK-2125: 2100*2500mm |

| Body Structure | Overall precision welding |

| Gantry | High-strength aviation aluminum integrated gantry structure |

| Feeding Method | Manual feeding/automatic feeding (optional) |

| Driving Mode | Intelligent digital control servo |

| Transmission Mode | Precision rack + linear guide |

| Table | Aviation aluminum vacuum adsorption platform + 4mm thick fiber tablecloth |

| Material Fixing Method | Vacuum adsorption |

| CNC System | Full touch LCD display |

| Transmission Port | USB, network port |

| Fan | 5.5KW/7.5KW/9KW (optional) three-phase AC vortex vacuum adsorption fan |

| Vision Positioning Cutting | Camera, projector (optional) |

| Optional Tools | Vibrating knife, circular knife, pneumatic knife, drag knife, creasing, beveling, punching, etc. (optional) |

| Operating Voltage | AC 220V/380V 50Hz-60Hz |

| Security System | Infrared sensor + emergency stop switch (double protection) |

| Maximum Pocessing Speed | 0-1500mm/s (depending on the material) |

REVIEWS

Let more people know what you share.