[Function Description]

Automatic loading and unloading ATC CNC Router has automatic tool changing function, and also adds full-automatic loading and unloading function, which saves loading and unloading time, greatly improves processing efficiency and saves labor costs.

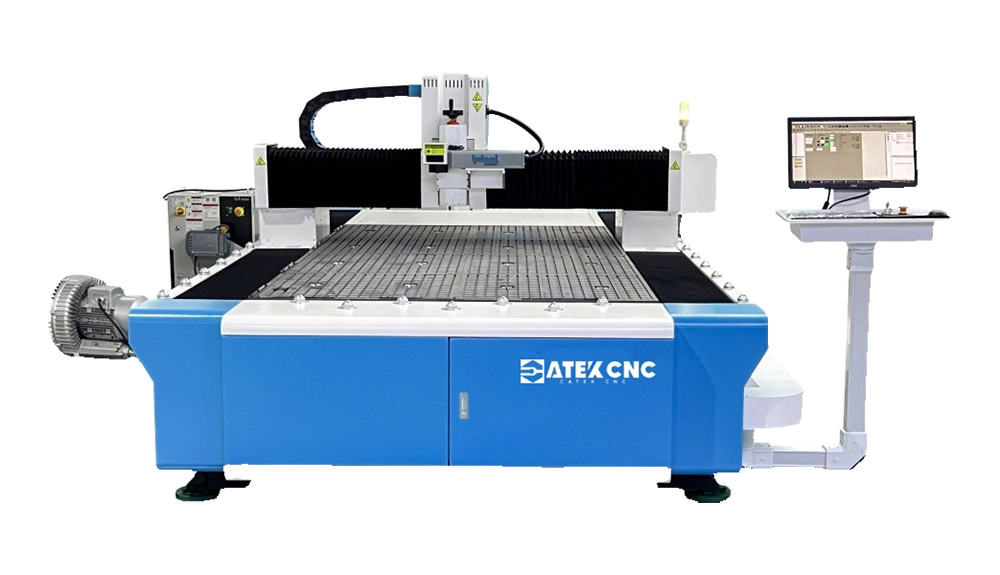

Overview of ATC CNC Router With Automatic Loading & Unloading

Automatic loading and unloading ATC CNC Router has automatic tool changing function, and also adds full-automatic loading and unloading function.The loading and unloading platforms are fully automatically raised and lowered, and the suction cups hold the materials tightly to realize automatic loading. After the plate processing is completed, the unloading platform is used to realize automatic unloading. It can be operated unmanned, which greatly saves labor costs. This allows the operator to focus on other work, and one person can look after multiple machines.

Advantages of ATC CNC Router With Automatic Loading & Unloading

Use 9KW fully automatic tool-changing air-cooled spindle, the maximum speed can reach 24000r/m, which can quickly process various types of plates, with large torque and large feed volume.

The transmission method uses TBI high-precision ball screw, high-precision helical rack, with 30mm guide rails and 30mm linear bearings, with fast running speed and low processing noise.

The XYZ axes all use 1.5KW high-power servo motors, and the Z axis uses a brake motor, all of which are used in conjunction with the Japanese imported Shinpo planetary reducer, which has higher precision, shorter braking time, and doubled efficiency.

The whole machine uses a heavy-duty bed, which has been treated with high temperature and processed by five-sided gantry milling. It uses a heavy-duty thickened gantry and heightened and weighted support columns, making the processing more stable and the machine more durable.

Using 11KW water ring vacuum pump, 6-zone 24-hole vacuum adsorption table, both large and small plates can be adsorbed and processed normally, making it more convenient to use.

4+2 positioning cylinders are used together to process 4*8 feet plates, which makes plate positioning more convenient and increases processing efficiency.

Using the fully automatic tool setting instrument, no matter the size of the tool, you can use the fully automatic tool setting instrument to achieve one-click tool setting processing, which is more convenient to operate.

Equipped with a fully automatic loading platform, it can automatically control the lifting and lowering. The lifting distance can be set according to the thickness of the plate, and it can cooperate with the machine's loading suction cup to achieve fully automatic loading.

The fully automatic rolling unloading platform, after the plate processing is completed, cooperate with the machine's automatic unloading device to automatically push the processed plate to the unloading platform for automatic unloading.

It uses Taiwan LNC numerical control system. It has more expansion functions and humanized design, is easy to operate, and supports fully automatic loading and unloading platform.You can also add an automatic labeling machine to optimize the complex processing flow and realize assembly line work.

Equipped with a straight-row tool-changing magazine, it can hold 8/12/16 tools. For products with complex processes, it can achieve fully automatic tool change and complete the processing in one go.

Application Scope of ATC CNC Router With Automatic Loading & Unloading

Applicable Materials:

Suitable for wood boards, density boards, artificial boards, particle boards, gypsum boards, multilayer boards, plastics, PVC, PCB, acrylic, Chevron boards, PTFE boards, aluminum-plastic boards, aluminum, copper and other types of boards.

Applicable Industries:

Furniture Industry: Cabinets, cabinet doors, wooden doors, mahogany furniture, wooden furniture accessories, whole house furniture customization, office furniture, etc.

Decoration Industry: Bookshelves, screens, cat climbing frames, wall panels, wooden decorative paintings, etc.

Advertising Industry: Advertising word cutting, luminous words, crystal words, acrylic, PCB, gypsum board, etc.

ATC CNC Router With Automatic Loading & Unloading Technical Parameters

| Model | CK-1325-TA |

| XYZ Work Schedule | 300*2500*200mm(customizable according to processing requirements) 4*8 |

| Gantry | Thickened aged steel gantry, steel beams, thickened gantry columns |

| Lathe Bed | Independent anti-interference control cabinet for machining center bed (heavy duty bed) |

| Spindle | HQD 9KW high power air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/m |

| Driving Mode | High torque 1.5KW pure servo motor drive * 4 (Z axis uses brake motor) |

| Reducer | Japan Shimpo reducer |

| Tool Change Magazine | 8/12/16 straight tool magazine |

| Table | Vacuum table 6 partitions, 24 wells |

| Vacuum Pump | 11KW water ring vacuum pump |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan high precision 30 linear square rail/30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW Double-barrel Bag Vacuum Cleaner |

| Control System | Taiwan LNC cutting machine dedicated control system |

| Lubrication System | Oil injection maintenance system |

| Operating Voltage | AC380V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, JDpaint, etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Positioning | 4+2 Positioning Cylinder |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Pushing | Fully automatic push cylinder device |

| Loading | Automatic lifting loading platform |

| Unloading | Automatic rolling conveyor unloading platform |

| Maximum Pocessing Speed | 28000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 4600kg |

| Expanded Size | 9850*2150*2200mm |

Optional Accessories for ATC CNC Router With Automatic Loading & Unloading Technical

| Spindle | Italian HSD spindle/Italian HITECO spindle |

| Control System | Syntec/NCStudio etc. |

| Saw Blades | The saw knife can be rotated to cut the board |

| 5+4 Pneumatic Drilling Kit | HQD 5+4 Pneumatic Drilling Kit |

| Pressure Roller | Double rod independent pneumatic pressure rollers can be individually controlled to fix the plate |

| Labeling Machine | Fully automatic printing, typesetting and labeling machine |

Detailed Introduction of ATC CNC Router With Automatic Loading & Unloading

Automatic feeding platform

Automatic unloading platform

The following are the processable products of ATC CNC Router With Automatic Loading & Unloading for your reference

| Model | CK-1325-TA |

| XYZ Work Schedule | 300*2500*200mm(customizable according to processing requirements) 4*8 |

| Gantry | Thickened aged steel gantry, steel beams, thickened gantry columns |

| Lathe Bed | Independent anti-interference control cabinet for machining center bed (heavy duty bed) |

| Spindle | HQD 9KW high power air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/m |

| Driving Mode | High torque 1.5KW pure servo motor drive * 4 (Z axis uses brake motor) |

| Reducer | Japan Shimpo reducer |

| Tool Change Magazine | 8/12/16 straight tool magazine |

| Table | Vacuum table 6 partitions, 24 wells |

| Vacuum Pump | 11KW water ring vacuum pump |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan high precision 30 linear square rail/30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW Double-barrel Bag Vacuum Cleaner |

| Control System | Taiwan LNC cutting machine dedicated control system |

| Lubrication System | Oil injection maintenance system |

| Operating Voltage | AC380V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, JDpaint, etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Positioning | 4+2 Positioning Cylinder |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Pushing | Fully automatic push cylinder device |

| Loading | Automatic lifting loading platform |

| Unloading | Automatic rolling conveyor unloading platform |

| Maximum Pocessing Speed | 28000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 4600kg |

| Expanded Size | 9850*2150*2200mm |

REVIEWS

Let more people know what you share.