[Function Description]

5x10-Foot Plasma Cutter For Sheet & Tube can not only cut plates, but also tubes. This machine has multiple functions and advantages in cutting tubes, and is suitable for cutting various metal tubes. It can realize the functions of short section, cutting, opening and through-line cutting of tubes, etc. It is flexible and simple to operate, and can meet the needs of different industrial production applications.

Overview of 5x10-Foot Plasma Cutter For Sheet & Tube

5x10-Foot Plasma Cutter For Sheet & Tube can not only cut plates, but also tubes. This machine has multiple functions and advantages in cutting tubes, and is suitable for cutting various metal tubes. It can realize the functions of short section, cutting, opening and through-line cutting of tubes, etc. It is flexible and simple to operate, and can meet the needs of different industrial production applications.

Advantages of 5x10-Foot Plasma Cutter For Sheet Metal & Tube

High efficiency and high precision:

The CNC plasma cutter can cut at extremely high speeds, usually up to 10,000mm/min or more, and have higher cutting accuracy than flame cutting. It uses a CNC system for control, which can automatically and accurately control the cutting process, thereby achieving clean and consistent cutting.

Wide range of material applicability:

The CNC plasma cutter can cut various metal plates, including stainless steel, cast iron, copper, aluminum and other non-ferrous metals. In addition, it can also cut some materials that are difficult to handle with traditional methods.

Energy saving and environmental protection:

The CNC plasma cutter have significant energy-saving effects, and the use of water during cutting can eliminate noise, dust, harmful gases and arc light pollution, effectively improving the working environment.

Easy operation and maintenance:

The CNC plasma cutter is easy to learn, fully functional and user-friendly. It adopts modular design, quick installation and easy movement. In addition, the CNC system is equipped with automatic arc ignition, stable performance, supports G-code path files generated by various software, and is easy and fast to operate.

Reduced need for secondary processing:

The CNC plasma cutter produce less scum, and the attached scum is easier to remove, usually without grinding or scraping, greatly reducing the time required for secondary processing. The cut surface is smooth, with little thermal deformation and almost no heat-affected zone.

Flexibility and versatility:

The CNC plasma cutter is not only suitable for cutting irregular shapes on flat surfaces, but also for cutting complex shapes and designs. It can also be used for planing, marking and cutting rusty metals, and after adding a rotating axis, it can be used for cutting metal pipes.

Cost-effectiveness:

The CNC plasma cutter show great advantages in saving materials and improving labor productivity. Its cost is much lower than laser cutting, but the cutting quality is close to the level of fiber laser cutting.

5x10-Foot Plasma Cutter For Sheet Metal & Tube Technical Parameters

| Model | CK-1530-PT |

| Work Area | 1500mm*3000mm |

| Power | 63A/120A/160A/200A/300A/400A |

| Gas | Oxygen |

| Application | Metal fabrications |

| Guideway | Taiwan Hiwin square guide rail + X Y rack and Z ball screw |

| Relay Accessories | Schneider |

| Torch Height Controller | Standard high sensitivity arc voltage device |

| Driving System | Leadshine motor and driver |

| Control System | Starfire control system |

| Lubrication System | Electric lubricating oil pot |

| Operating Voltage | 220V/380V 50/60Hz |

| Nesting Software | FASTCAM |

| File Output Mode | USB interface |

| Instruction Format | G code |

| Repeat Positioning Accuracy | ±0.05mm |

| Process Precision | ±0.35mm |

| Maximum Pocessing Speed | 12000mm/min |

| Weight | 1600kg |

| Expanded Size | 3830*3060*1580mm |

Detailed Introduction of 5x10-Foot Plasma Cutter For Sheet Metal & Tube

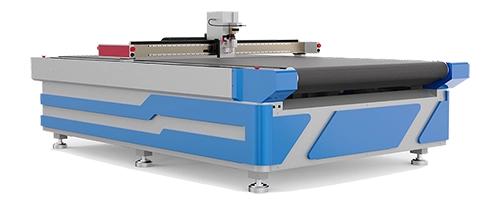

Plasma cutting head

CNC plasma cutting head with fast perforation and cutting of metal materials

Knife strip platform

Distributed knife strip platform with good thermal conductivity and without easy to stick

Plasma generator

American Hypertherm/China Huayuan high-quality high-frequency plasma generator

Control system

Starfire control system Support cutting process settings break point positioning and other advanced functions

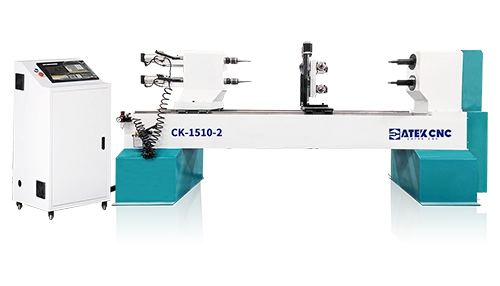

Rotary pipe cutting machine

The Rotary pipe cutting machine can be used for cutting metal round pipes.

The following are the processable products of 5x10-Foot High Performance Plasma Cutter

| Model | CK-1530-PT |

| Work Area | 1500mm*3000mm |

| Rotation Size | Diameter 10-500mm, Length 3000mm-6000mm |

| Power | 63A/120A/160A/200A/300A/400A |

| Gas | Oxygen |

| Application | Metal fabrications |

| Guideway | Taiwan Hiwin square guide rail + X Y rack and Z ball screw |

| Relay Accessories | Schneider |

| Torch Height Controller | Standard high sensitivity arc voltage device |

| Driving System | Leadshine motor and driver |

| Control System | Starfire control system |

| Lubrication System | Electric lubricating oil pot |

| Operating Voltage | 220V/380V 50/60Hz |

| Nesting Software | FASTCAM |

| File Output Mode | USB interface |

| Instruction Format | G code |

| Repeat Positioning Accuracy | ±0.05mm |

| Process Precision | ±0.35mm |

| Maximum Pocessing Speed | 12000mm/min |

| Weight | 1600kg |

| Expanded Size | 3830*3060*1580mm |

REVIEWS

Let more people know what you share.