[Function Description]

The five-axis woodworking machining center is a high-end CNC machine with five independent motion axes, including three linear axes (X, Y, Z) and two rotary axes (A and C). This unique structure enables the five-axis machining center to achieve precise cutting and processing of all surfaces of the workpiece through the linkage control of the five axes in one clamping.

Overview of Five-Axis Wood Processing Center

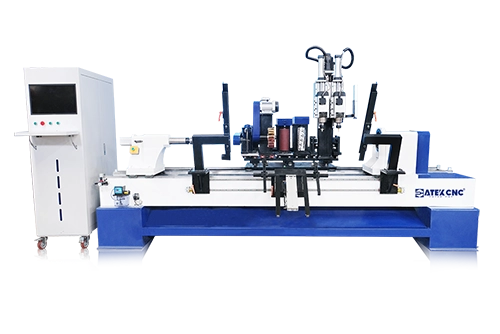

The five-axis drilling and milling woodworking machining center is a high-end CNC machine with five independent motion axes, including three linear axes (X, Y, Z) and two rotary axes (A and C). This unique structure enables the five-axis machining center to achieve precise cutting and processing of all surfaces of the workpiece through the linkage control of five axes in one clamping.

The five-axis drilling and milling woodworking machining center is widely used in the woodworking industry and has significant advantages in the processing of complex and special-shaped workpieces such as solid wood furniture and MDF boards. It can complete multiple processes at one time, such as milling, drilling, sawing, edging, chamfering, hollowing, etc., and is suitable for the processing of various complex curved surfaces, bevels, oblique holes and three-dimensional lines. In addition, it can also avoid tool interference, improve processing efficiency and accuracy, and is suitable for the manufacture of various complex parts.

The five-axis drilling and milling machining center is equipped with a four-sided tool changer and a CNC system, which can reduce manual intervention and improve production efficiency and consistency. At the same time, it also has self-diagnosis and self-repair functions to ensure the stability and safety of the system.

Advantages of Five-Axis Wood Processing Center

Turret rotating axis:

The rotating tool changing structure uses imported RV reducer, which has high positioning accuracy and can realize multi-axis linkage processing; the spindle motor used is a double-head high-speed rotating spindle, which can be equipped with 4 rows of different types of tools at the same time, and automatically rotates and switches during processing, which has higher processing efficiency.

Servo rotating tooling;

After the wood is installed, the servo motor drives the reducer to rotate, and the wood rotates at the same time to start processing; processing multiple products at a time, improving production efficiency and reducing production costs.

Material discharge and support device:

When the machine tool stops, the support positioning device rises, and the lifting height can be adjusted according to the specifications of the wood, and the support point position can also be adjusted according to the shape of the wood; it can fix various shapes of wood, and it is easier to fix the wood.

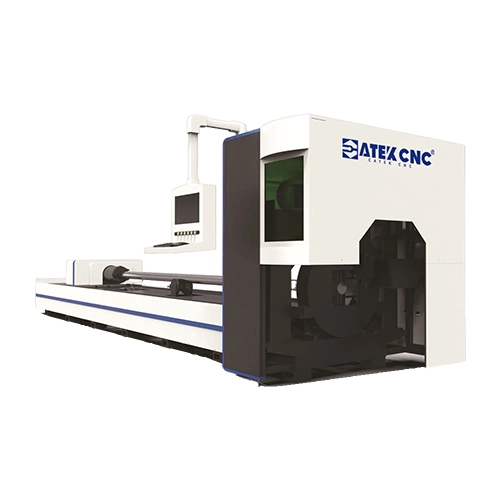

Fully enclosed protective cover;

The fully enclosed dustproof cover is equipped with 4 large-diameter dust suction ports. By connecting the dust suction device, the dust generated during processing is reduced; it can realize fully automatic dust suction and dust-free processing.

Control box;

The main electrical appliances are imported electrical components; the driving motor is Delta high-torque servo motor, and the main circuit is equipped with filters to eliminate interference and ensure the stability of the control system.

Control system:

Using Taiwan Baoyuan bus control system, it is simple to operate and easy to get started.

Lubrication and maintenance system:

The machine is equipped with a fully automatic timing oil pump device, and the oil circuit at the far end and the oil circuit at the near end are separately controlled for lubrication to avoid the oil circuit being too far away and causing inability to lubricate; affecting machine processing.

Automatic chip removal:

The machine is equipped with an automatic chip removal device, and the wood dust generated during the processing can be automatically sent out through the chip removal trough, which is convenient for cleaning and maintenance of the equipment.

Application Scope of Five-Axis Wood Processing Center

The application range of the five-axis drilling and milling wood processing center is very wide, covering multiple industries and fields. It can process complex solid wood furniture parts, such as mortise and tenon products, sofa legs, solid wood furniture curved surface milling, grooving and drilling, etc. In addition, it is also widely used in various fields such as architectural woodworking, craft creation, prototyping, model making, sign making and engraving.

Woodworking engraving industry;

Mold processing industry;

Home appliance trimming and milling;

Bathroom and luggage industry;

Aviation, motor vehicle, wind power, RV, yacht, wooden house, handicraft and other modeling processing;

PVC/PP/PE, polylong, anti-bite, glass fiber, carbon fiber, resin, wood substitute and other new material processing;

Copper, aluminum and other non-ferrous metal cutting and milling processing;

Musical instruments, coffin materials, shoe molds and other industries.

Five-Axis Wood Processing Center Technical Parameters

| Model | CK-1219-4、CK-1219-4B、CK-1219-8、CK-1219-12 |

| Processing Dimensions | 1200mm long * 230mm diameter(customizable according to processing requirements) |

| Spindle Power | 5.5KW*8 + 3.7KW*8 |

| Spindle Speed | 12000-18000r/min |

| Spindle Spacing | Spindle Spacing |

| Electrical Parts | Schneider |

| Frequency Converter | BEST heavy-duty inverter |

| Pneumatic Components | AirTac |

| Screw | Taiwan TBI ball screw |

| Guideway | German Roster dustproof steel belt |

| RV Reducer | Taiwan TSUNTIEN |

| X-Axis Motor | 1.5KW Delta servo |

| Y-Axis Motor | 1.5KW Delta servo |

| Z-Axis Motor | 1.5KW Delta servo |

| A-Axis Motor | 1.5KW Delta servo |

| B-Axis Motor | 1.5KW Delta servo |

| Control System | Taiwan LNC |

| Operating Voltage | 200V 60Hz |

| Total Power | About 89KW |

| Maximum No-Load Running Speed | 20m/min |

| Weight | 5500kg |

| Expanded Size | 4100*2100*2650mm |

Detailed Introduction of Five-Axis Wood Processing Center

Four-head five-axis wood processing center

Double-station four-head five-axis wood processing center

Eight-head five-axis wood processing center

Twelve-head five-axis wood processing center

Spindle

The spindle uses a high-speed air-cooled motor with high speed and good processing effect.

Servo motor

Servo rotary tooling, servo motor drives the reducer to rotate, and multiple pieces of wood are rotated and processed at the same time.

Control system

Taiwan LNC bus control system, easy to operate; the electrical part uses high-performance servo drive and high-power heavy-load spindle inverter.

Lubrication system

The machine is equipped with an automatic timing oil pumping device, and the remote oil circuit and the near oil circuit are controlled separately to avoid inadequate lubrication due to the oil circuit being too far away.

Automatic chip removal device

The machine is equipped with an automatic chip removal device. The wood chips generated during the processing can be sent out through the chip removal groove, which is convenient for cleaning and maintenance of the equipment.

The following are the processable products of Five-Axis Wood Processing Center

| Model | CK-1219-4、CK-1219-4B、CK-1219-8、CK-1219-12 |

| Processing Dimensions | 1200mm long * 230mm diameter(customizable according to processing requirements) |

| Spindle Power | 5.5KW*8 + 3.7KW*8 |

| Spindle Speed | 12000-18000r/min |

| Spindle Spacing | 280mm |

| Electrical Parts | Schneider |

| Frequency Converter | BEST heavy-duty inverter |

| Pneumatic Components | AirTac |

| Screw | Taiwan TBI ball screw |

| Guideway | German Roster dustproof steel belt |

| RV Reducer | Taiwan TSUNTIEN |

| X-Axis Motor | 1.5KW Delta servo |

| Y-Axis Motor | 1.5KW Delta servo |

| Z-Axis Motor | 1.5KW Delta servo |

| A-Axis Motor | 1.5KW Delta servo |

| B-Axis Motor | 1.5KW Delta servo |

| Control System | Taiwan LNC |

| Operating Voltage | 200V 60Hz |

| Total Power | About 89KW |

| Maximum No-Load Running Speed | 20m/min |

| Weight | 5500kg |

| Expanded Size | 4100*2100*2650mm |

REVIEWS

Let more people know what you share.

The price of this machine is quite high. I need a machine that can process complex products. After repeated comparisons, I decided to buy this machine. After a long wait, I finally got the machine and installed it. When I saw the appearance of this machine, I knew that the time and money spent were worth it.