[Function Description]

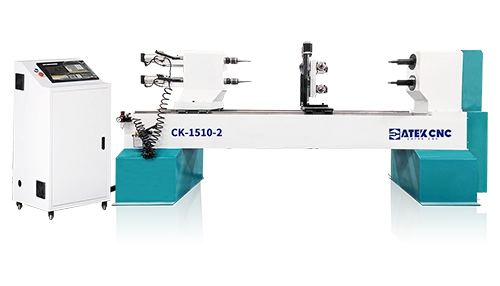

The single-tool automatic feeding CNC woodworking lathe reduces one tool and adds automatic loading and unloading functions based on the 1530. It is suitable for low-budget users who need automatic loading and unloading.

Overview of Single-Knife Wood Lathe With Automatic Loading & Unloading

The single-tool automatic feeding CNC woodworking lathe reduces one tool and adds automatic loading and unloading functions based on the 1530. It is suitable for low-budget users who need automatic loading and unloading.

The X-axis tool performs rough processing on the wood. Compared with ordinary woodworking, the processing volume is larger, which can greatly improve the processing efficiency. For ordinary small wooden products with a diameter of less than 100mm, one cut can be formed. Using the CNC system, large wooden products can be made automatically and intelligently.It can be flexibly equipped with a variety of CNC tools. For different products, it can be equipped with a tool holder of more than 30mm for more efficient processing. The machine uses a side-tilted automatic feeding structure, which is easier to adjust. You only need to put the wood to be processed into the silo, simply adjust the center point, and click the start button to start automatic processing. Each axis of the machine is equipped with a safety sensor limit. During processing, it can automatically alarm and stop when it senses illegal operations. It is more suitable for small factories or production workshops that lack manual labor. One person can take care of multiple machines and only needs to continuously feed the machine. Grinding wheels, grinding rollers, etc. can be selected. After processing, the product can be polished and polished, eliminating the trouble of secondary polishing. It can also be equipped with a high-speed air-cooled spindle to perform drilling, grooving, etc. on the product. It is more convenient to manufacture some furniture table legs and furniture accessories and other products, saving time for secondary processing.Whether you are a small processing plant or a batch production plant, you can use this 1530 automatic feeding CNC wood lathe to help your production.

Advantages of Single-Knife Wood Lathe With Automatic Loading & Unloading

Single-knife processing, equipped with a large-size center sleeve, can achieve a single processing volume of more than 50mm, fully automatic cylinder top material, simple operation.

Use multiple cylinders to run in conjunction to achieve fully automatic loading and unloading, one-button start, and one person can manage multiple machines

The main motor uses a 5.5KW high-torque high-speed motor and is equipped with a high-torque inverter. Even if it processes 200mm large-size materials, it can be easily processed.

Optional functional configurations such as grinding wheels and air-cooled spindles can save the trouble of secondary grinding, drilling, and grooving.

Using the LCD screen CNC system, the system's built-in macro program can automatically process G codes, eliminating the trouble of using software to generate G codes, and is more convenient to use.

Using Taiwan's HIWIN guide rails, flange sliders, and TBI high-precision ball screws, the accuracy is higher.

Application Scope of Single-Knife Wood Lathe With Automatic Loading & Unloading

Applicable Materials:

Wood, plastic, acrylic, nylon, PVC, carbon fiber, artificial wood substitutes, etc.

Applicable Industries:

Furniture: table legs, chair legs, sofa legs, bed legs, pool table legs, stair railings, Roman columns, etc.

Musical instruments: piano legs, flutes, suona, bassoons, drumsticks, etc.

Sports: baseball bats, wooden balls, chess, etc.

Other products: wooden handles, wooden bowls, vases, plates, cups, etc.

Single-Knife Wood Lathe With Automatic Loading & Unloading Technical Parameters

| Model | CK-1530-A |

| Processing Dimensions | 1500 * 300mm (customizable according to processing requirements) |

| Lathe Bed | Heavy-duty integral casting bed, independent anti-interference control cabinet |

| Electrical Machinery | 5.5KW three-phase asynchronous rotating motor |

| Driving Mode | YAKO driver |

| Motor Speed | 0-6000rpm/min |

| Frequency Converter | BEST/Hypmont inverter |

| Transmission Mode | XY axis 25TBI high-precision ball screw transmission, Z axis uses high-precision helical rack/TBI 32 ball screw |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail/25 flange slider |

| Equipment Cable | Pure copper anti bending cable |

| Control System | CatekCNC dedicated control system panel, CK1000TC |

| Loading & Unloading Device | Multi-linked cylinder loading rack (simple and easy to use) |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, solidworks UG powermill, etc. |

| Engraving Instructions | Standard G code, u00,mmg,plt |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Expanded Size | 3100*1450*1650mm |

Detailed Introduction of Single-Knife Wood Lathe With Automatic Loading & Unloading

Single-Knife Wood Lathe automatic loading part

Precautions when using Single-Knife Wood Lathe With Automatic Loading & Unloading

During processing, you need to confirm the machine speed and air pressure.

When processing products without reserved products at both ends of the wood, you need to confirm that the diameter of the ejector pins at both ends is smaller than the diameter of the product to be processed.

When processing products, you need to use a suitable feed speed to ensure the processing effect.

Before processing, you need to modify the machine parameters.

After the machine processing is completed, the machine needs to be lubricated and maintained.

The following are the processable products of Single-Knife Wood Lathe With Automatic Loading & Unloading

| Model | CK-1530-A |

| Processing Dimensions | 1500 * 300mm (customizable according to processing requirements) |

| Lathe Bed | Heavy-duty integral casting bed, independent anti-interference control cabinet |

| Electrical Machinery | 5.5KW three-phase asynchronous rotating motor |

| Driving Mode | YAKO driver |

| Motor Speed | 0-6000rpm/min |

| Frequency Converter | BEST/Hypmont inverter |

| Transmission Mode | XY axis 25TBI high-precision ball screw transmission, Z axis uses high-precision helical rack/TBI 32 ball screw |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail/25 flange slider |

| Equipment Cable | Pure copper anti bending cable |

| Control System | CatekCNC dedicated control system panel, CK1000TC |

| Loading & Unloading Device | Multi-linked cylinder loading rack (simple and easy to use) |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, solidworks UG powermill, etc. |

| Engraving Instructions | Standard G code, u00,mmg,plt |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Expanded Size | 3100*1450*1650mm |

REVIEWS

Let more people know what you share.

During use, the comfort of this woodworking lathe made me feel good and reduced operating fatigue.