[Function Description]

This small lathe is specially designed for processing various small handicrafts, toys, chess, etc. It has complete functions and automatic feeding function, which can realize fully automatic processing of small products.

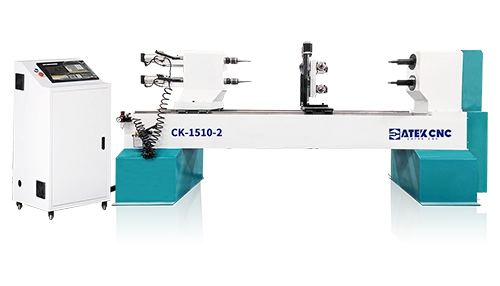

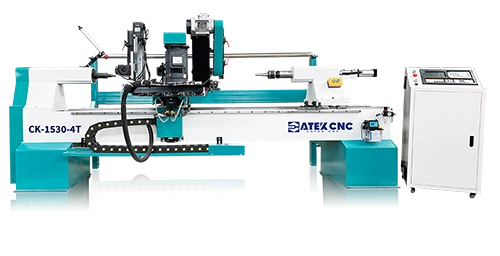

Overview of Small Crafts CNC Wood Lathe

This small lathe is specially designed for processing various small handicrafts, toys, chess, etc. It has complete functions and automatic feeding function, which can realize fully automatic processing of small products.

The machine is equipped with a turning tool, a cutting tool, an internal hole tool, and a drill, which can be adjusted and used according to the processed products. It is simple and convenient.

Use multiple combined cylinder structures to run in conjunction to achieve fully automatic feeding, one-button operation to start, the entire material is automatically cut off, and the material is automatically fed after processing is completed.

The pneumatic chuck can be replaced at will according to the material diameter, square materials and round materials can be selected at will, and the material bin can be adjusted at will according to the length of the raw materials.

Use 3KW brake motor with a speed of 6000rpm/min, millisecond-level braking, and higher efficiency.

It has complete functions and can be used for turning, cutting, punching and hollowing. The functions can be combined arbitrarily.

Self-developed CNC software, which can set the processing method arbitrarily according to the raw material size and product drawing, is simple and easy to use.

Advantages of Small Crafts CNC Wood Lathe

Improve processing efficiency and use Small Crafts CNC Wood Lathe to process wooden handles, drawer handles and other similar products with higher efficiency. One person can look after dozens of machines, with high processing efficiency and fast speed, saving manual labor.

Fast production speed, processing small wooden handles, an average of 600-1500 pieces can be produced per day.

Save wood. Traditional manual chuck lathes waste a section of raw materials in the clamping position for each product processed. The new small CNC woodworking lathe does not need to waste the clamping position, which can reduce waste and continue processing.

The operation is simple. The machine adopts CNC control system for fully automatic processing. Before processing, you only need to use the CNC system to calibrate the tool and then you can start processing. No human intervention is required during the processing.

Application Scope of Small Crafts CNC Wood Lathe

Handles: wooden handles, drawer handles, skipping rope handles, pot handles and other handles

Crafts: vases, pen holders, cups, jars, bracelets, etc.

Other products: chess, wooden toys, wooden figures, dolls, wooden balls, chess, etc.

Small Crafts CNC Wood Lathe Technical Parameters

| Model | CK-0615-A、CK-0715-A、CK-0820-A |

| Processing Dimensions | CK-0615-A: 60mm diameter*150mm length (customizable)、CK-0715-A: 70mm diameter*150mm length (customizable)、CK-0820-A: 80mm diameter*200mm length (customizable) |

| Lathe Bed | Heavy-duty integral casting bed, independent anti-interference control cabinet |

| Electrical Machinery | 3KW brake motor |

| Driving Mode | YAKO driver |

| Motor Speed | 3000rpm/min |

| Driving Mode | XY axis 25TBI ball screw drive |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail/25 flange slider |

| Equipment Cable | Pure copper anti bending cable |

| Control System | Dedicated control system panel, CK-1000TC (matching pulse handwheel) |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/50/60Hz OR AC220V/50/60Hz (customizable) |

| Compatible Software | Artcam, AutoCAD, CDR, Illustrator, etc. (including self-developed simple drawing software) |

| Engraving Instructions | Standard G code, u00,mmg,plt |

| Loading & Unloading Device | Multi-linked cylinder loading rack (simple and easy to use) |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 750kg |

| Expanded Size | 4100*1100*1350mm |

Detailed Introduction of Small Crafts CNC Wood Lathe

Shape/Drilling/Cutting

Standard contouring tools, cutting tools, and drill bits can automatically feed, contour, drill, and cut, allowing the operator to focus on other tasks. Contour processing can be automatically layered, and the drilling depth can be automatically processed in multiple times. Compared with ordinary small CNC woodworking lathes, the processing efficiency is higher, and drilling work can be performed at the same time, eliminating the trouble of secondary processing and drilling.

Fully automatic feeding

Fully automatic feeding only requires simple adjustments to the machine settings to start working. Multiple cylinders work in conjunction with each other to load materials automatically. The whole material is fed in at one time and the material is processed and cut automatically, which greatly saves labor and saves manual material placement, allowing the operator to focus on other work. The operator only needs to put the material in on time, which greatly improves the efficiency of processing and production. The loading tray can be adjusted to fit a maximum of 800mm wooden sticks and place multiple wooden sticks at one time.

CATEKCNC dedicated control system panel

CATEKCNC dedicated control system, equipped with industrial machine display, can operate in the most stringent environment. CK1000TC

control system has the following features:

With USB reading G code drawing function

G code can be written manually to run the machine quickly

Specially designed, the interface is more powerful and easier to operate

Can store more than 5,000+ drawings

Grinding wheel

The following are the processable products of Small Crafts CNC Wood Lathe

| Model | CK-0615-A |

| Processing Dimensions | CK-0615-A: 60mm diameter*150mm length (customizable)、CK-0715-A: 70mm diameter*150mm length (customizable)、CK-0820-A: 80mm diameter*200mm length (customizable) |

| Lathe Bed | Heavy-duty integral casting bed, independent anti-interference control cabinet |

| Electrical Machinery | 3KW brake motor |

| Driving Mode | YAKO driver |

| Motor Speed | 3000rpm/min |

| Driving Mode | XY axis 25TBI ball screw drive |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail/25 flange slider |

| Equipment Cable | Pure copper anti bending cable |

| Control System | Dedicated control system panel, CK-1000TC (matching pulse handwheel) |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/50/60Hz OR AC220V/50/60Hz (customizable) |

| Compatible Software | Artcam, AutoCAD, CDR, Illustrator, etc. (including self-developed simple drawing software) |

| Engraving Instructions | Standard G code, u00,mmg,plt |

| Loading & Unloading Device | Multi-linked cylinder loading rack (simple and easy to use) |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 750kg |

| Expanded Size | 4100*1100*1350mm |

REVIEWS

Let more people know what you share.

I needed some chess pieces to be machined, and at first I was worried about the quality of the machine-made products. So I went directly to their factory to see for myself, and they showed me the machine-made products on the spot. They even sent a special person to pick me up at the airport, and I was very satisfied. :)