[Function Description]

This CNC lathe has three functions that can be switched automatically. Compared with the standard model 1530, it has a multi-function spindle, which makes it more comprehensive and applicable.

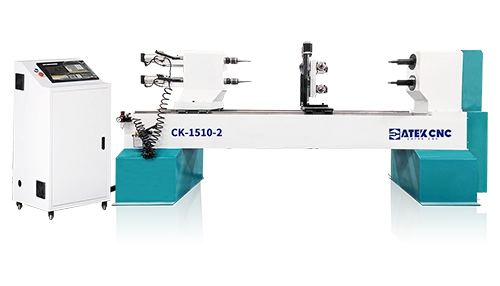

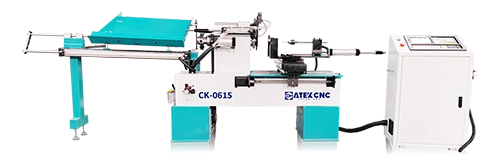

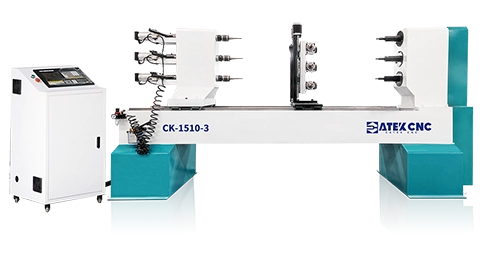

Overview of Fully Automatic Three-Switch CNC Wood Lathe

This CNC lathe has three functions that can be switched automatically. Compared with the standard model 1530, it has a multi-function spindle, which makes it more comprehensive and applicable.

Turning, grinding, planing, drilling, grooving, four-axis 3D engraving, multiple functions are integrated into one, which can complete the processing of products that require multiple processes at one time.

Advantages of Fully Automatic Three-Switch CNC Wood Lathe

The machine is driven by a full servo motor. The XYZ three-axis drivers are all connected by high-precision TBI ball screws. They are driven by servo drivers and run in conjunction with Hiwin guide rails/slides to achieve silent operation.

Each function is driven by an independent cylinder and can be switched at will. When processing, you only need to move the tool to the starting point of the material to start processing. The pulse handwheel operation makes tool setting more convenient.

The main motor uses a 4KW high-speed rotating servo motor, which can switch between speed mode and position mode at will, with a maximum speed of 6000r/m, and can switch the A-axis to rotate at any angle.

It uses a 3.5KW high-speed air-cooled rotary spindle, can clamp any shank diameter tool within 12.7, has a maximum speed of 18000r/m, can be equipped with a carving knife, runs a four-axis NC path, and realizes four-axis linkage operation, which is used to process various complex and special-shaped products.

It uses a 230mm high, 90mm large diameter independent heavy-cutting planer, driven by an independent high-torque motor, with a speed of up to 3000r/m, which can be used for rough processing and milling of materials.

Use independent cylinder to control the grinding wheel to run grinding and polishing. A single product can be polished multiple times or partially polished. Grinding belts or grinding rollers can be selected for different products.

Using professional industrial CNC system, each function is equipped with independent button control. The machine uses international standard G code, and each function has a corresponding G code control switch, which is easy to operate.

Application Scope of Fully Automatic Three-Switch CNC Wood Lathe

Applicable Materials:

Suitable for use on various materials such as wood, PVC, plastic, nylon, acrylic, carbon fiber, bamboo, density board, etc.

Applicable Industries:

Furniture: tables, chairs, sofas, beds, stair railings, pool tables, etc.

Musical instruments: drumsticks, flute, suona, cucurbit flute, bassoon, piano, etc.

Sports equipment: pool cues, baseball bats, wooden balls, etc.

Crafts: wooden bowls, vases, cups, pen holders, nesting dolls, wooden guns, candlesticks, etc.

Sculptures: figure sculptures, animal sculptures, totem sculptures, text sculptures, etc.

It can be used to process various difficult special-shaped products such as solid wood stair columns, solid wood sofa legs, solid wood table and chair legs, billiard table legs, tiger legs, horse legs, bed legs, special-shaped curved legs, sports equipment, musical instruments, solid wood handicrafts, carving products, various furniture accessories, etc.

Fully Automatic Three-Switch CNC Wood Lathe Technical Parameters

| Model | CK-1530-3T |

| Processing Dimensions | 1500 * 300mm (customizable according to processing requirements) |

| Lathe Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Electrical Machinery | 4KW pure servo high torque high-speed rotating motor |

| Driving Mode | The XY axis uses a 750W high torque servo motor, and the Z-axis uses a 1.8KW high torque servo motor |

| Frequency Converter | HPMONT frequency converter/pure servo frequency converter |

| Spindle Servo Motor Speed | 0-6000r/m |

| Spindle Power | HQD 3.5KW high-speed air-cooled variable frequency spindle |

| Spindle Speed | 0-18000rpm/min |

| Planer | 90 * 240mm, large diameter independent planer, 2.2KW three-phase asynchronous motor drive |

| Grinding Wheel | 230 * 50mm, independently controlled grinding wheel, driven by 370w three-phase asynchronous motor |

| Transmission Mode | XY axis 25TBI ball screw transmission, Z-axis uses high-precision helical gear rack/TBI 32 ball screw |

| Turning Tool | V-shaped alloy cutting tool (large cutting capacity) |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail/25 flange slider |

| Equipment Cable | Pure copper anti bending cable |

| Automatic Loading & Unloading | Multi cylinder linkage automatic feeding system |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/3PH/50/60Hz OR AC220V/3PH/50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, carving, powermill, artcam, etc. |

| Engraving Instructions | Standard G code, u00,mmg,plt |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1850kg |

| Expanded Size | 3550*2300*1750mm |

| Features | Automatic feeding, turning, planing, milling, 3D engraving, slotting, drilling, grinding, polishing |

Detailed Introduction of Fully Automatic Three-Switch CNC Wood Lathe

Demonstration of three independent processing functions

Demonstration of four independent processing functions

Demonstration of five independent processing functions

CK-1000TC control system

What types of products can be processed using a Fully Automatic Three-Switch CNC Wood Lathe?

| Model | CK-1530-3T |

| Processing Dimensions | 1500 * 300mm (customizable according to processing requirements) |

| Lathe Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Electrical Machinery | 4KW pure servo high torque high-speed rotating motor |

| Driving Mode | The XY axis uses a 750W high torque servo motor, and the Z-axis uses a 1.8KW high torque servo motor |

| Frequency Converter | HPMONT frequency converter/pure servo frequency converter |

| Spindle Servo Motor Speed | 0-6000r/m |

| Spindle Power | HQD 3.5KW high-speed air-cooled variable frequency spindle |

| Spindle Speed | 0-18000rpm/min |

| Planer | 90 * 240mm, large diameter independent planer, 2.2KW three-phase asynchronous motor drive |

| Grinding Wheel | 230 * 50mm, independently controlled grinding wheel, driven by 370w three-phase asynchronous motor |

| Transmission Mode | XY axis 25TBI ball screw transmission, Z-axis uses high-precision helical gear rack/TBI 32 ball screw |

| Turning Tool | V-shaped alloy cutting tool (large cutting capacity) |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail/25 flange slider |

| Equipment Cable | Pure copper anti bending cable |

| Automatic Loading & Unloading | Automatic Loading & Unloading |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/3PH/50/60Hz OR AC220V/3PH/50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, carving, powermill, artcam, etc. |

| Engraving Instructions | Standard G code, u00,mmg,plt |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1750kg |

| Expanded Size | 3550*1550*1450mm |

REVIEWS

Let more people know what you share.