[Function Description]

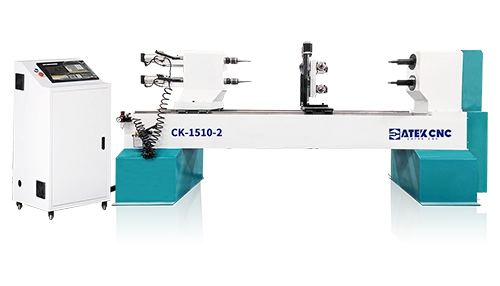

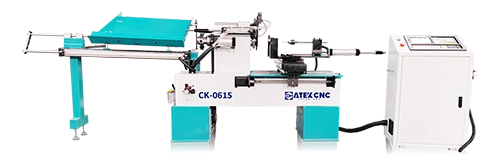

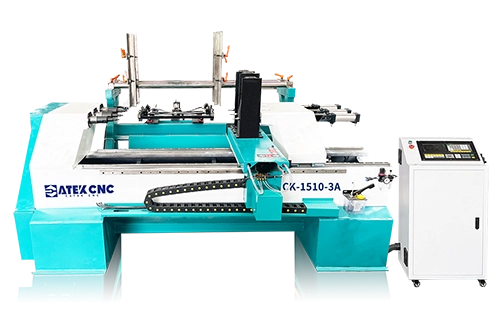

The double-knife 1530 lathe has a stable structure, simple operation and low price. It is more suitable for traditional woodworking work, start-up workers and personal studios.

Overview of Double Blade CNC Wood Lathe

The double-knife 1530 lathe has a stable structure, simple operation and low price. The machine is compatible with and can recognize various versions of DXF format drawings, traditional NC drawings, or G-code drawings in DBF, TXT and other formats. On the computer, use CAD, CAM and other types of software to copy the 2D plane drawings of the products to be processed to the U disk, and then import them into the machine to start processing. Only simple settings are required to move the tool to the starting point of wood processing, and the machine can start processing. The operation is simple and can start processing in 1-2 hours. Whether you are a CNC novice or a CNC expert, you can easily master the operation of this CNC woodworking lathe, and the double-knife 1530 CNC woodworking lathe has a wide range of versatility. Whether it is processing wooden handles, stair railings, sofa legs, table legs, chair legs, bed legs, drumsticks, baseball bats, wooden bowls, vases or other wooden products, the double-knife 1530 CNC woodworking lathe can be used.

The double-knife 1530 CNC woodworking lathe is more suitable for junior entrepreneurs, amateurs and personal studios, as well as some small factories. One person can operate multiple machines, and the machine can be equipped with automatic feeding function or grinding function, which can realize automatic feeding and automatic grinding and polishing. CATEKCNC can provide you with a full range of customization.

Advantages of Double Blade CNC Wood Lathe

Double-knife wood turning, double efficiency, high-speed feeding, the knives are all controlled by independent drive motors, and the precision controllable range is 0.01mm.

The whole machine is made of black pig iron high-temperature tempering casting, five-sided gantry milling, and the guide rail installation platform is processed once to ensure that the bed will not deform during long-term use.

The main motor uses a 5.5KW high-power three-phase asynchronous motor, which is controlled by a high-torque motor protection inverter. The speed can be adjusted at will, and the speed can be adjusted according to the different processing raw materials.

CATEKCNC dedicated control system, equipped with industrial LCD display and pulse handwheel, simple operation, more convenient tool setting.

Application Scope of Double Blade CNC Wood Lathe

Applicable Materials:

Wood, plastic, acrylic, nylon, PVC, carbon fiber, artificial wood substitutes, etc.

Applicable Industries:

Furniture: table legs, chair legs, sofa legs, bed legs, pool table legs, stair railings, Roman columns, etc.

Musical instruments: piano legs, flutes, suona, bassoons, drumsticks, etc.

Sports: baseball bats, wooden balls, chess, etc.

Other products: wooden handles, wooden bowls, vases, plates, cups, etc.

Double Blade CNC Wood Lathe Technical Parameters

| Model | CK-1530 |

| Processing Dimensions | 1500 * 300mm (customizable according to processing requirements) |

| Lathe Bed | Heavy-duty integral high-temperature tempered black cast iron full-cast bed, integral cast iron spindle box, integral cast iron tailstock, independent control cabinet (better anti-interference performance) |

| Electrical Machinery | 5.5KW three-phase asynchronous rotating motor |

| Driving Mode | YAKO driver |

| Frequency Converter | Best high torque inverter |

| Motor Speed | 0-6000rpm/min (Continuously variable speed) |

| Transmission Mode | XY axis 25TBI high-precision ball screw transmission, Z axis uses high-precision helical rack/TBI 32 ball screw |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail/25 flange slider |

| Equipment Cable | Pure copper anti bending cable |

| Automatic Loading & Unloading | Multi cylinder linkage automatic feeding system |

| Control System | Customized dedicated control system panel, CK1000TC, high-definition LCD display screen, industrial-grade dedicated |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/3PH/50/60Hz OR AC220V/3PH/50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, carving, powermill, UCancam, etc. |

| Engraving Instructions | Standard G code, u00,mmg,plt |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Processing Accuracy | ±0.05mm |

| Ejector/Chuck | M55*2/Mohs No. 5 |

| Air Pressure | 0.6mpa↑ |

| Weight | 1840kg |

| Expanded Size | 3100mm*1300mm*1450mm |

Detailed Introduction of ATC CNC Router

Double Blade CNC Wood Lathe with Grinding Wheel

Double Blade CNC Wood Lathe with Grinding Wheel with Chuck

Double Blade CNC Wood Lathe with Grinding Wheel with Automatic Tool Changer

CK-1000TC control system

DSP handle(optional)

DSP-132

DSP-136

Four-jaw chuck(optional)

Optional self-centering chuck is used for processing wooden crafts, such as wooden bowls, vases, cups and other products. It can also be used to clamp wood. One end is clamped by the chuck and the other end is fixed by the ejector. It is more stable for processing large products.

The following are the processable products of Double Blade CNC Wood Lathe for your reference

Issues to note when choosing a CNC wood lathe

There are many issues to pay attention to when buying a CNC woodworking lathe. First, you need to confirm your processing size, the processing length and diameter of the product, and the processing process. For example: (punching, grooving, grinding, milling).

You need to confirm your voltage. The standard voltage of the CNC woodworking lathe supports 380V 3PH/220V 3PH/220V 1PH. In addition, we can provide you with voltage customization. If you have special voltage requirements, such as (440V, 550V, etc.), you can contact our sales specialist to customize the transformer for you to ensure that the machine can be used normally.

If you need to make handicrafts (such as vases, wooden bowls), you can choose a combination of a four-jaw chuck and an inner hole cutter, or use an automatic tool changer to save the time of manual tool change. Turn the product to be processed to the shape of the product you need, then use a four-jaw chuck to clamp the product on the machine tool, and use an inner hole cutter to process the inner hole of the product.

| Model | CK-1530 |

| Processing Dimensions | 1500 * 300mm (customizable according to processing requirements) |

| Lathe Bed | Heavy-duty integral high-temperature tempered black cast iron full-cast bed, integral cast iron spindle box, integral cast iron tailstock, independent control cabinet (better anti-interference performance) |

| Electrical Machinery | 5.5KW three-phase asynchronous rotating motor |

| Driving Mode | YAKO driver |

| Frequency Converter | Best high torque inverter |

| Motor Speed | 0-6000rpm/min (Continuously variable speed) |

| Transmission Mode | XY axis 25TBI high-precision ball screw transmission, Z axis uses high-precision helical rack/TBI 32 ball screw |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail/25 flange slider |

| Equipment Cable | Pure copper anti bending cable |

| Control System | Customized dedicated control system panel, CK1000TC, high-definition LCD display screen, industrial-grade dedicated |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/3PH/50/60Hz OR AC220V/3PH/50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, carving, powermill, UCancam, etc. |

| Engraving Instructions | Standard G code, u00,mmg,plt |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Processing Accuracy | ±0.05mm |

| Ejector/Chuck | M55*2/Mohs No. 5 |

| Air Pressure | 0.6mpa↑ |

| Weight | 1840kg |

| Expanded Size | 3100mm*1300mm*1450mm |

REVIEWS

Let more people know what you share.

They recommended this machine to me, I told them my needs, they recommended this machine to me, that's all, it's not bad, I'm still learning how to use this machine.

Намного лучше, чем моя предыдущая ручная машина, которая, если честно, была мусором, и оригинальная машина должна была потратить много времени, чтобы гарантировать точность обработки, которая вводилась в чертежи

I am very grateful to Mr. Wang, the supplier's technician. He is very patient and has very solid skills. He taught me from the simplest and solved a series of difficult problems for me.