[Function Description]

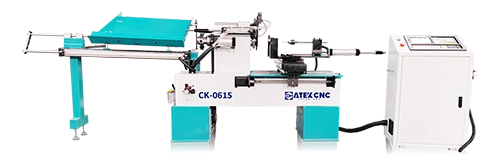

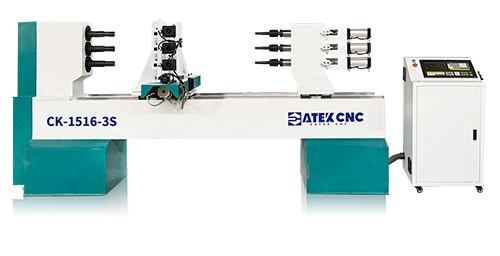

Single-Axis Wood Lathe For Pool Cue With Automatic Loading & Unloading is specially designed for processing slender products such as billiard cues. The machine has automatic loading and unloading functions, which can realize unattended fully automatic operation.

Overview of Single-Axis Wood Lathe For Pool Cue With Automatic Loading & Unloading

Single-Axis Wood Lathe For Pool Cue With Automatic Loading & Unloading is specially designed for processing slender products such as billiard cues. The machine has automatic loading and unloading functions, which can realize unattended fully automatic operation.

Advantages of Single-Axis Wood Lathe For Pool Cue With Automatic Loading & Unloadinge

It can be used to process various slender products, using high-speed air-cooled spindle for fast milling, smooth surface and high efficiency.

The machine uses a full cast iron bed, spindle box, and tailstock. The machine assembly accuracy is strictly controlled and the precision of the processed products can be controlled within 0.05mm.

The main motor uses a 5.5KW high-speed motor and is equipped with an independent frequency converter. The speed can be adjusted at will within 3000 rpm, making it more convenient to use.

Special CNC system and external pulse handwheel can adjust the product within 0.01mm.

Fully automatic loading and unloading of processing materials, you only need to simply adjust the settings of the machine to start working, and multiple cylinders work in a fully automatic manner.

Application Scope of Single-Axis Wood Lathe For Pool Cue With Automatic Loading & Unloading

The pool cue CNC wood lathe can be applied to various types of products such as pool cues, crutches, wooden sticks, wooden handles, walking sticks, trekking poles, round table legs, etc. It can not only be used to process wood, but also various synthetic materials such as plastic, acrylic, glass fiber, carbon fiber, etc., with a wide range of applications.

Single-Axis Wood Lathe For Pool Cue With Automatic Loading & Unloading Technical Parameters

| Model | CK-1510-A |

| Processing Dimensions | Maximum length 1500mm * maximum diameter 100mm(customizable according to processing requirements) |

| Lathe Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW three-phase asynchronous motor |

| Motor Speed | 0-3000r/m |

| Driving Mode | YAKO driver |

| Frequency Converter | BEST inverter |

| Spindle | 3.5KW high-speed air-cooled variable frequency spindle |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | XY axis 25TBI ball screw drive, Z axis uses high-precision helical rack/TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CatekCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, solidworks UG powermill, etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Loading & Unloading Device | Multi-linked cylinder loading rack (simple and easy to use) |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Expanded Size | 3100*1400*1500mm |

Detailed Introduction of Single-Axis Wood Lathe For Pool Cue With Automatic Loading & Unloading

The following are the processable products of Single-Axis Wood Lathe For Pool Cue With Automatic Loading & Unloading

| Model | CK-1510-A |

| Processing Dimensions | Maximum length 1500mm * maximum diameter 100mm (customizable according to processing requirements) |

| Lathe Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW three-phase asynchronous motor |

| Motor Speed | 0-3000r/m |

| Driving Mode | YAKO driver |

| Frequency Converter | BEST inverter |

| Spindle | 3.5KW high-speed air-cooled variable frequency spindle |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | XY axis 25TBI ball screw drive, Z axis uses high-precision helical rack/TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CatekCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, solidworks UG powermill, etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Loading & Unloading Device | Multi-linked cylinder loading rack (simple and easy to use) |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Expanded Size | 3100*1400*1500mm |

REVIEWS

Let more people know what you share.