[Function Description]

The double-axis turning, milling and carving CNC wood lathe is more suitable for mass production of some stair columns, sofa legs, table legs and other products. It can process two identical products at a time, and perform turning, punching, grooving, milling, 3D carving and other work on the product shape. It is more friendly to some products that need to be produced in large quantities.

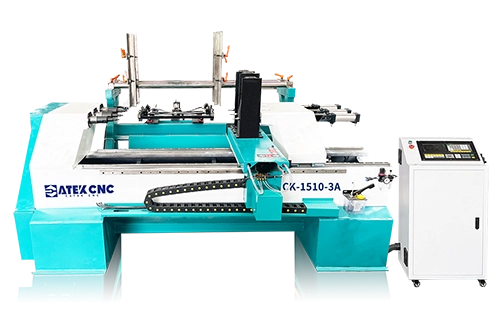

Overview of Double-Axis Multifunctional CNC Wood Lathe

The double-axis turning, milling and carving CNC wood lathe is specially designed for mass production and processing. It is more suitable for mass production of some stair columns, sofa legs, table legs and other products. It can process two identical products at a time, and perform turning, punching, grooving, milling, 3D carving and other work on the product shape. It is more friendly to some products that need to be produced in large quantities, can improve production efficiency and processing efficiency, save more labor, compared with single-axis, the same processing time can increase processing efficiency two times at a time, the machine is designed and processed with four knives, and is equipped with two 3.5KW high-speed air-cooled spindles. After processing, the product can be punched, slotted and other processes to make processing simpler. At the same time, it is equipped with a two-hole large-diameter center sleeve, which is specially designed for some thinner and longer products. It is more friendly to the processing of some thinner and longer products. Whether you are a processing and production factory or a personal studio, the CK-1516-2S double-axis turning, milling and engraving CNC wood lathe can greatly help your work!

Advantages of Double-Axis Multifunctional CNC Wood Lathe

There are two turning tools on each X-axis and Y-axis, and the single-side tool is driven independently, so the roughing and forming can be done in one step, which is more efficient.

The two spindles on the side are driven by independent cylinders for operation and processing, with a maximum speed of 18000rpm/m, which can easily process and process the materials.

Using a 4KW high-speed servo rotary motor, it supports the position mode/speed mode dual mode switching at will, and the A-axis angle can be accurately controlled to 0.001°.

An optional fully automatic centering frame makes the installation of the material center point simpler. You only need to lean lightly and turn on the cylinder switch to clamp the wood.

Application Scope of Double-Axis Multifunctional CNC Wood Lathe

Furniture: tables, chairs, sofas, beds, wooden stairs, etc.

Sports: axe handles, hammer handles, wooden balls, baseball bats, etc.

Music: bassoon, suona, Hulusi, flute, etc.

Crafts: wooden figures, wooden toys, wooden bowls, wooden basins, etc.

Three-Axis Multifunctional CNC Wood Lathe Technical Parameters

| Model | CK-1516-2S |

| Processing Dimensions | 1500mm long * 160mm diameter * 2 pieces (the maximum diameter of a single piece is 300mm, the processing size can be customized) |

| Lathe Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW pure servo rotary motor |

| Motor Speed | 0-6000r/m |

| Driving Mode | Servo drive |

| Frequency Converter | BEST inverter/servo frequency conversion drive |

| Spindle | 3.5KW high-speed air-cooled variable frequency spindle*2 |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | XY axis 25TBI ball screw drive, Z axis uses high-precision helical rack/TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail/25 slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CatekCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, solidworks UG powermill, etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Expanded Size | 3100*1400*1550mm |

Detailed Introduction of Double-Axis Multifunctional CNC Wood Lathe

The following are the processable products of Double-Axis Multifunctional CNC Wood Lathe

| Model | CK-1516-2S |

| Processing Dimensions | 1500mm long * 160mm diameter * 2 pieces (the maximum diameter of a single piece is 300mm, the processing size can be customized) |

| Lathe Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW pure servo rotary motor |

| Motor Speed | 0-6000r/m |

| Driving Mode | Servo drive |

| Frequency Converter | BEST inverter/servo frequency conversion drive |

| Spindle | 3.5KW high-speed air-cooled variable frequency spindle*2 |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | XY axis 25TBI ball screw drive, Z axis uses high-precision helical rack/TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail/25 slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CatekCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, solidworks UG powermill, etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Expanded Size | 3100*1400*1550mm |

REVIEWS

Let more people know what you share.