[Function Description]

The new heavy-duty double-axis four-knife CNC wood lathe is a CNC wood lathe that is more suitable for small processing plants. This CNC wood lathe is easy to operate, has a fast processing speed, and is cheap. You can get this lathe for only $5,000. This lathe can process two pieces of wood at a time, and four knives are fed in at the same time, which is suitable for batch processing of the same products.

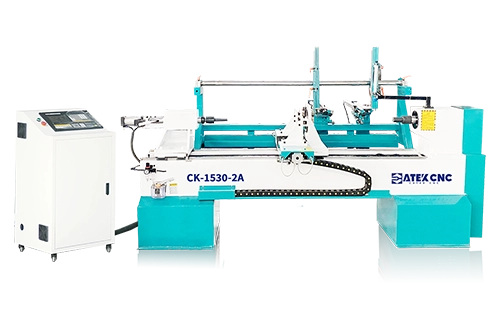

Overview of Double-Axis Four-Knife CNC Wood Lathe

The new heavy-duty double-axis four-knife CNC wood lathe is a CNC wood lathe that is more suitable for small processing plants. This CNC wood lathe is easy to operate, has a fast processing speed, and is cheap. You can get this lathe for only $5,000. This lathe can process two pieces of wood at a time, and four knives are fed in at the same time, which is suitable for batch processing of the same products.The processing length of 600mm and the diameter of 60mm can be completed in only about 80 seconds. The processing efficiency is high, and more than 500 products can be easily processed every day, which can save you more labor and production costs. It uses a 5.5KW high-torque three-phase asynchronous large motor and can adjust the speed arbitrarily through the inverter control. The maximum processing length of this machine is 1.5m, and the maximum processing diameter of two is 160mm. If only one is processed at a time, it can be used to process products with a diameter of 300mm. The machine has a wider application and can customize the processing size for you. The processing length and processing diameter can be customized arbitrarily.

Advantages of Double-Axis Four-Knife CNC Wood Lathe

Two axes and four knives can process two pieces of wood at a time, two knives feed at the same time, X axis roughing, Y axis finishing, higher efficiency.

Adopt independent control box, equipped with dual cooling fans, can effectively isolate interference.

Use 5.5KW three-phase asynchronous large motor, greater torque, and high-power inverter, can accurately control the speed.

Use Morse ejector, easy to replace, power shaft can be replaced with four-claw chuck, stable clamping.

Heavy-duty integral full casting bed, spindle box and tailstock are cast by high-temperature tempering, more stable to use and no deformation.

Application Scope of Double-Axis Four-Knife CNC Wood Lathe

Heavy-duty double-axis four-knife CNC wood lathes have a wide range of uses and are widely used in various industries, wooden furniture accessories, furniture, building materials and other products in daily life, including various wooden ornaments, wooden bowls, vases, wooden cups that can be seen everywhere, frequently used sporting goods, baseball bats, musical instruments commonly used drumsticks, flutes, bassoons and other wind instruments, or piano tables, piano stools and other products.

Double-Axis Four-Knife CNC Wood Lathe Technical Parameters

| Model | CK-1516-2 |

| Processing Dimensions | 1500mm long * 160mm diameter * 2 pieces (the maximum diameter of a single piece is 300mm, the processing size can be customized) |

| Lathe Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 5.5KW three-phase asynchronous motor |

| Motor Speed | 0-6000r/m |

| Driving Mode | YAKO driver |

| Frequency Converter | BEST/Hypmont high torque inverter |

| Transmission Mode | XY axis 25TBI ball screw drive, Z axis uses high-precision helical rack/TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail/25 slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CatekCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, solidworks UG powermill, etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Expanded Size | 3100*1400*1500mm |

Detailed Introduction of Double-Axis Four-Knife CNC Wood Lathe

Double-Axis Four-Knife CNC Wood Lathe with grinding

The following are the processable products of Double-Axis Four-Knife CNC Wood Lathe

| Model | CK-1516-2 |

| Processing Dimensions | 1500mm long * 160mm diameter * 2 pieces (the maximum diameter of a single piece is 300mm, the processing size can be customized) |

| Lathe Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 5.5KW three-phase asynchronous motor |

| Motor Speed | 0-6000r/m |

| Driving Mode | YAKO driver |

| Frequency Converter | BEST/Hypmont high torque inverter |

| Transmission Mode | XY axis 25TBI ball screw drive, Z axis uses high-precision helical rack/TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail/25 slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CatekCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, solidworks UG powermill, etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Expanded Size | 3100*1400*1500mm |

REVIEWS

Let more people know what you share.