[Function Description]

Plasma cutter is a metal cutting machine. When cutting metal of small thickness, the cutting speed is extremely fast, and the cutting surface is smooth, the thermal deformation is small, and there is almost no heat-affected zone.

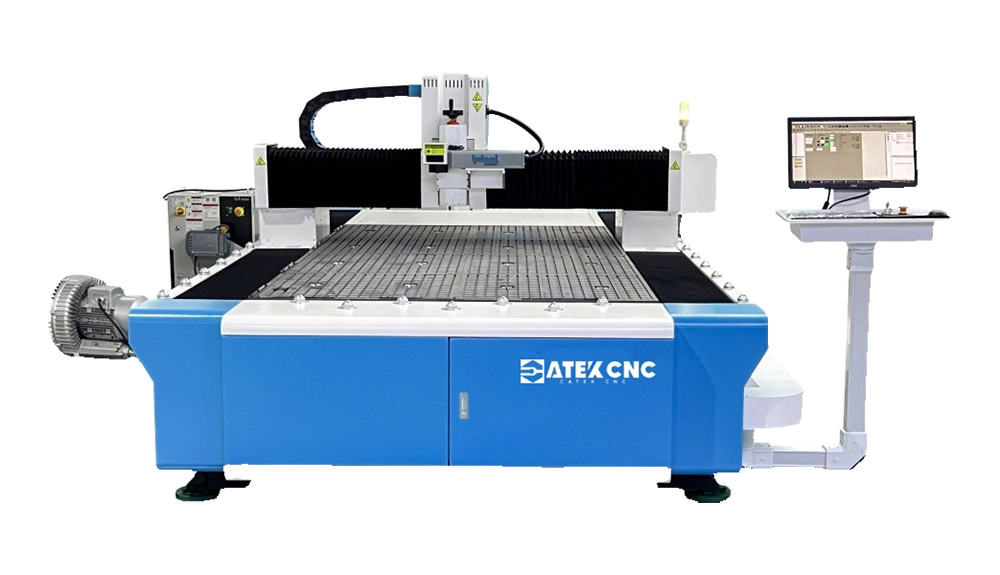

Overview of 4x8-Foot High Performance Plasma Cutter

The 4x8-foot high-quality CNC plasma cutter is an automatic cutter with a CNC plasma system. Compared with the traditional handheld plasma, it has upgraded a set of CNC systems and a set of motor drive systems, which can fully automatically cut various shapes. It is equipped with a 4x8-foot processing platform, which can place a whole sheet of metal at a time, and nest the layout through CNC software to achieve fully automatic cutting processing. And the price is cheap, which is more suitable for metal plate cutting work in home studios, small production workshops or various industrial manufacturing.

Advantages of 4x8-Foot High Performance Plasma Cutter

Use high-quality plasma cutting head, CNC high-precision processing, high concentricity, multi-faceted heat dissipation design, better heat dissipation performance, and special high-conductivity copper rod.

Use STARFIRE flame plasma cutting system, support multiple languages, adopt industrial-grade ARM chip, suitable for various working environments.

It uses a plasma-specific sword-grid table with high levelness, which can hold raw materials of any size. The tail of the machine is equipped with a high-power exhaust fan, which ensures stable operation.

Use Huayuan plasma power supply, 100% (40℃) high load duration, super load operation, and American Hypertherm plasma power supply can be selected.

Application Scope of 4x8-Foot High Performance Plasma Cutter

4*8 feet CNC plasma cutter has a wide range of uses and can process a wide range of materials. It is suitable for cutting and punching various metals, such as iron, stainless steel, carbon steel, alloy steel, aluminum plate, copper, titanium alloy, magnesium, nickel, chromium iron, and other metal plates. Below I will list the industries it can be used for:

Metal cutting

Advertising manufacturing

Decoration industry

Metal doors and windows

Construction industry

Metal art manufacturing

Agricultural machinery

Automotive industry

Other mass production industries.

4x8-Foot High Performance Plasma Cutter Technical Parameters

| Model | CK-1325-P |

| Work Area | 1300mm*2500mm |

| Power | 63A/120A/160A/200A/300A/400A |

| Gas | Oxygen |

| Application | Metal fabrications |

| Guideway | Taiwan Hiwin square guide rail + X Y rack and Z ball screw |

| Relay Accessories | Schneider |

| Torch Height Controller | Standard high sensitivity arc voltage device |

| Driving System | Leadshine motor and driver |

| Control System | Starfire control system |

| Lubrication System | Electric lubricating oil pot |

| Operating Voltage | 220V/380V 50/60Hz |

| Nesting Software | FASTCAM |

| File Output Mode | USB interface |

| Instruction Format | G code |

| Repeat Positioning Accuracy | ±0.05mm |

| Process Precision | ±0.35mm |

| Maximum Pocessing Speed | 12000mm/min |

| Weight | 1100kg |

| Expanded Size | 3330*2060*1580mm |

Detailed Introduction of 4x8-Foot High Performance Plasma Cutter

Plasma cutting head

CNC plasma cutting head with fast perforation and cutting of metal materials

Knife strip platform

Distributed knife strip platform with good thermal conductivity and without easy to stick

Plasma generator

American Hypertherm/China Huayuan high-quality high-frequency plasma generator

Control system

Starfire control system Support cutting process settings break point positioning and other advanced functions

The following are the processable products of 4x8-Foot High Performance Plasma Cutter

| Model | CK-1325-P |

| Work Area | 1300mm*2500mm |

| Power | 63A/120A/160A/200A/300A/400A |

| Gas | Oxygen |

| Application | Metal fabrications |

| Guideway | Taiwan Hiwin square guide rail + X Y rack and Z ball screw |

| Relay Accessories | Schneider |

| Torch Height Controller | Standard high sensitivity arc voltage device |

| Driving System | Leadshine motor and driver |

| Control System | Starfire control system |

| Lubrication System | Electric lubricating oil pot |

| Operating Voltage | 220V/380V 50/60Hz |

| Nesting Software | FASTCAM |

| File Output Mode | USB interface |

| Instruction Format | G code |

| Repeat Positioning Accuracy | ±0.05mm |

| Process Precision | ±0.35mm |

| Maximum Pocessing Speed | 12000mm/min |

| Weight | 1100kg |

| Expanded Size | 3330*2060*1580mm |

REVIEWS

Let more people know what you share.