[Function Description]

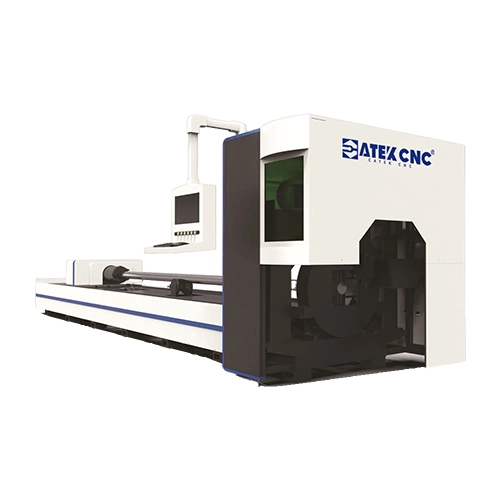

The closed fiber laser marking machine adopts an integrated overall structure and air cooling system, equipped with a sturdy protective shell and open cover protection function, which reduces optical pollution and has the characteristics of high efficiency and low maintenance.

Overview of Enclosed Fiber Laser Marking Machine

Fully enclosed fiber laser marking machines have many advantages that make them perform well in industrial applications. First of all, the enclosed design can effectively prevent pollution and odor. At the same time, the machine uses laser marking technology, and no dangerous factors such as sparks will be generated during the processing, providing users with a safer working environment. Enclosed fiber laser marking machines usually adopt an integrated overall structure and air cooling system, which reduces optical pollution and has the characteristics of high efficiency and low maintenance.

Using a fully enclosed protective cover and a smoke exhaust fan, the smoke and odor in the processing process can be completely discharged, reducing the odor generated when used indoors.

The electric lifting scale can adjust the appropriate focal length according to the height of the processed product. It is used with a lifting platform, which is suitable for processing products of various heights and is easy to adjust. The rotating axis can also be optionally installed to process 3D stereo products.

Advantages of Enclosed Fiber Laser Marking Machine

Safety protection:

The fully enclosed fiber laser marking machine is equipped with a sturdy protective shell and cover protection function, which can effectively prevent laser radiation from causing harm to operators. In addition, it is also equipped with a laser protection glass observation window, which allows operators to observe the machine processing effect and progress at any time in a safe environment.

High electro-optical conversion rate and beam quality:

The fully enclosed fiber laser marking machine uses high-quality fiber lasers with high electro-optical conversion efficiency, good beam quality, and very small spot, which can achieve ultra-fine marking. This high-precision marking effect makes it suitable for marking various fine and complex patterns.

Stability and durability:

The fully enclosed fiber laser marking machine has stable operation, high positioning accuracy, long service life, and low operating cost. It can generally run maintenance-free for more than ten years, which can greatly reduce processing costs. Its structural layout is reasonable, moisture-proof and dust-proof, and is suitable for use in workshops with harsh environments.

Environmental protection and low noise:

The fully enclosed fiber laser marking machine adopts air cooling and is equipped with a fully automatic exhaust fan, which can exhaust all the odor and smoke of the processed products, without optical pollution and power loss, low noise, and meets environmental protection requirements.

Versatility and automated configuration:

The fully enclosed fiber laser marking machine can be configured with various functions according to your needs, supporting the marking of numbers, letters, Chinese characters, graphics, QR codes and other contents, and the software is powerful, with optional 3D rotating axis, automatic lifting platform, manual lifting platform, automatic focus, etc.

Wide range of applications:

The closed fiber laser marking machine is suitable for processing a variety of materials, especially for marking high hardness, high melting point, and brittle materials. Its application areas include electronic components, automotive parts, medical equipment, home appliances and other industries.

Application Scope of Enclosed Fiber Laser Marking Machine

The fully enclosed multifunctional fiber laser marking machine can engrave metal materials and some non-metallic materials, and is particularly suitable for some fields that require more precision and higher smoothness. It is suitable for various metals (steel, titanium, copper, gold, silver, including rare metals), industrial plastics, metal coating materials, ceramics, etc. It is widely used in mobile phone keys, electronic components, communication products, glasses and clocks, jewelry, luggage button decoration, stainless steel products, etc.

Enclosed Fiber Laser Marking Machine Technical Parameters

| Model | CK-11-FE |

| Laser Power | 20W/30W/50W/100W/200W |

| Laser Wavelength | 1064nm |

| Pulse Width | 20ns |

| Repetition Frequency Range | 1-600kHz |

| M2 | <1.8 |

| Maximum Single Pulse Energy | 1.25mJ |

| Output Power Stability | <5% |

| Output Beam Diameter | 7±0.5mm |

| Power Range | 0-100% |

| Marking Range | 110*110mm/200*200mm/300*300mm |

| Minimum Line Width | 0.01mm |

| Minimum Number Of Characters | 0.1mm |

| Marking Speed | ≤7000mm/s |

| Marking Depth | Depends on the materials |

| Repeatability Accuracy | ±0.001mm |

| Marking Format | Graphics, text, bar codes, QRcode, automatically date, batch number, serial number, etc. |

| Supported Graphics Formats | Ai, plt, dxf, dst, svg, nc, bmp, jpg, jpeg, gif, tga, png, tiff, tif |

| Fiber Cable Length | 3m |

| Rotation Axis | 80mm rotation axis |

| Operating Voltage | 220V±10%/50Hz or 110V±10%/60Hz or Customized |

| Unit Power | <0.5kw |

| Working Environment | Clean and dust free or dust less |

| Working Condition Humidity | 5%-75%, 0-40 degree, free of condensed water |

| Laser Lifetime | >100000 hours |

| Weight | 69kg |

| Expanded Size | 530*450*950mm |

The following are the processable products of Enclosed Fiber Laser Marking Machine

Use of fully enclosed fiber laser marking machine

Power-on steps:

Check whether the power input line is correct and intact, and whether the grounding is intact.

Turn on the main power supply and ensure that the machine is reliably grounded.

Turn on the main power switch and turn on the emergency stop switch to release it.

Turn on the computer and enter the marking software.

Marking operation:

Place the workpiece on the marking table and place it properly.

Turn on the laser power button, then press the galvanometer switch button, and all fans will start running.

Press the red light switch button and adjust the lifting table so that the two red lights overlap. This is the best focal length for laser marking.

Start marking and adjust parameters such as marking speed, frequency and laser power as needed.

Shutdown steps:

After marking, turn off the power of each component: laser switch, galvanometer switch, red light switch and key switch.

Exit all computer programs and shut down the computer.

| Model | CK-11-FE |

| Laser Power | 20W/30W/50W/100W/200W/300W |

| Laser Wavelength | 1064nm |

| Pulse Width | 20ns |

| Repetition Frequency Range | 1-600kHz |

| M2 | <1.8 |

| Maximum Single Pulse Energy | 1.25mJ |

| Output Power Stability | <5% |

| Output Beam Diameter | 7±0.5mm |

| Power Range | 0-100% |

| Marking Range | 110*110mm/200*200mm/300*300mm |

| Minimum Line Width | 0.01mm |

| Minimum Number Of Characters | 0.1mm |

| Marking Speed | ≤7000mm/s |

| Marking Depth | Depends on the materials |

| Repeatability Accuracy | ±0.001mm |

| Marking Format | Graphics, text, bar codes, QRcode, automatically date, batch number, serial number, etc. |

| Supported Graphics Formats | Ai, plt, dxf, dst, svg, nc, bmp, jpg, jpeg, gif, tga, png, tiff, tif |

| Fiber Cable Length | 3m |

| Operating Voltage | 220V±10%/50Hz or 110V±10%/60Hz or Customized |

| Unit Power | <0.5kw |

| Working Environment | Clean and dust free or dust less |

| Working Condition Humidity | 5%-75%, 0-40 degree, free of condensed water |

| Laser Lifetime | >100000 hours |

| Weight | 69kg |

| Expanded Size | 530*450*950mm |

REVIEWS

Let more people know what you share.