[Function Description]

The Multi-Headed CNC Router has multiple heads and can process multiple products at the same time, which can significantly save working time and ensure good consistency of the finished products when producing the same products in large quantities.

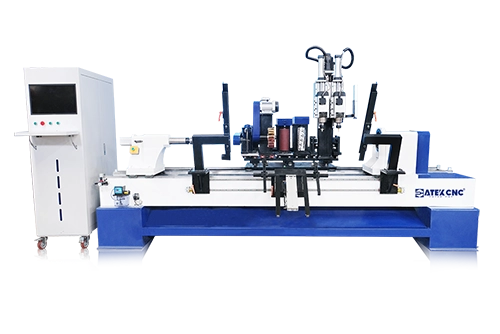

Overview of Multi-Headed CNC Router

The Multi-Headed CNC Router has multiple heads and can process multiple products at the same time, which can significantly save working time and ensure good consistency of the finished products when producing the same products in large quantities.

The multi-head CNC router has a wide range of uses. It can be used to process various furniture, furniture accessories, handicrafts, decoration materials and other products. You can customize the machine according to your actual requirements. The processing length, processing width and number of processing stations can all be customized according to your requirements. This machine can cut, mill, engrave, punch and other materials. No matter what you use it for, this machine can meet your needs.

Advantages of Multi-Headed CNC Router

Use one or more high-power high-speed water-cooled spindles for processing, with a maximum speed of 24000r/m, which can quickly process raw materials. (We can also equip you with air-cooled spindles according to your needs)

It can process multiple identical products at the same time, and the processing can be adjusted according to the product size. It is very suitable for mass production, greatly improving processing efficiency and ensuring product consistency.

The use of aviation-grade T-slot aluminum alloy platform, combined with the use of a mobile pressure plate to fix the plate, can quickly fix the product and is easy to use. A vacuum adsorption table or double-rod pneumatic pressure roller can be added as required.

Taiwan Hiwin guide rails/sliders are used, high-precision helical racks are used on the XY axis, and high-precision TBI ball screws are used on the Z axis to ensure fast positioning.

The bed is welded with heavy-duty thickened square tubes, the high-temperature tempered square steel gantry is integrated, and the heavy-duty thickened spindle hanging plate makes the processing and use more stable.

Application Scope of Multi-Headed CNC Router

Furniture: wooden furniture carving, wood board cutting, wood board punching, grooving, decorative board carving, classical furniture, bookshelves and other processing.

Crafts: wooden signs, portraits, decorations, wooden door decorations, three-dimensional reliefs, hollow carvings and other products.

Multi-Headed CNC Router Technical Parameters

| Model | CK-2030-6 |

| Processing Dimensions | 2000*3000*200mm (processing size and quantity can be customized) |

| Lathe Bed | Machining center processing bed (heavy duty bed), independent control cabinet |

| Gantry | Thickened cast iron gantry, thickened cast iron bracket |

| Spindle | 3.5KW high-speed water-cooled spindle*6 (spindle quantity/power can be customized) |

| Spindle Speed | 6000-24000r/m |

| Table | Aluminum Alloy T-Slot Table Top |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan Hiwin high precision 25 linear square rail |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Holdable Tool Shank Diameter | 3.175mm,4mm,6mm,12.7mm etc. |

| Control System | NCStudio v5.4.49 (support resuming carving after power outage) |

| Lubrication System | Oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, solidworks UG powermill, etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Pocessing Speed | 18000mm/min |

| Maximum No-Load Running Speed | 25000mm/min |

| Weight | 2400kg |

| Expanded Size | 3600*2500*1650mm |

Multi-Headed CNC Router Optional Configuration

| Control System | Richauto DSP controller/mach3/NCStudio etc. |

| Spindle | 1.5/2.2/3.5/4.5/6/7.5 etc. air-cooled, water-cooled variable frequency spindle. |

| Table | Vacuum adsorption platform/double rod pneumatic pressure roller |

| Drive motor | Yaskawa/Delta and other servo motors |

Detailed Introduction of Multi-Headed CNC Router

The following are the processable products of Multi-Headed CNC Router

| Model | CK-2030-6 |

| Processing Dimensions | 2000*3000*200mm (processing size and quantity can be customized) |

| Lathe Bed | Machining center processing bed (heavy duty bed), independent control cabinet |

| Gantry | Thickened cast iron gantry, thickened cast iron bracket |

| Spindle | 3.5KW high-speed water-cooled spindle*6 (spindle quantity/power can be customized) |

| Spindle Speed | 6000-24000r/m |

| Driving Mode | DORNA 1.5KW servo motor drive (Z-axis brake motor) |

| Table | Aluminum Alloy T-Slot Table Top |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan Hiwin high precision 25 linear square rail |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Holdable Tool Shank Diameter | 3.175mm,4mm,6mm,12.7mm etc. |

| Control System | NCStudio v5.4.49 (support resuming carving after power outage) |

| Lubrication System | Oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, solidworks UG powermill, etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Pocessing Speed | 18000mm/min |

| Maximum No-Load Running Speed | 25000mm/min |

| Weight | 2400kg |

| Expanded Size | 3600*2500*1650mm |

REVIEWS

Let more people know what you share.