[Function Description]

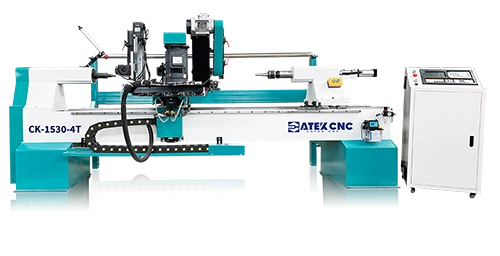

The double-knife automatic feeding CNC wood lathe adds automatic loading and unloading functions based on the 1530, which can realize unattended full-automatic processing and save manpower. Compared with the single-knife lathe, double-knife processing further improves processing efficiency.

Overview of Double-Knife Wood Lathe With Automatic Loading & Unloading

The double-knife automatic feeding CNC wood lathe adds automatic loading and unloading functions based on the 1530, which can realize unattended full-automatic processing and save manpower. Compared with the single-knife lathe, double-knife processing further improves processing efficiency.

The double-knife automatic feeding CNC wood lathe is specially designed and manufactured for factory workshops. During processing, you only need to put the wood into the material warehouse that has been adjusted in advance, and the processing materials can be loaded and unloaded automatically. You only need to simply adjust the machine settings to start working, and multiple cylinders are linked to work automatically. Fully automatic loading of materials, accurate positioning of the center point of the material. Automatic unloading of materials after processing, greatly saving labor, saving manual placement of materials, so that operators can focus on other work. Just put the materials in on time, greatly improving the efficiency of processing and production. The machine is more versatile, with a maximum processing length of 1500mm and a maximum processing diameter of 300mm. It can be adjusted and processed at will within this size. At the same time, the machine can be equipped with an optional grinding wheel, which can grind and polish the product synchronously during processing, or grind and polish the product separately, with high processing efficiency and fast speed. At the same time, the machine is equipped with a fixed follower bracket as standard, with a built-in large center bearing, high-speed rotation, and a center sleeve. It is customized according to the material size, and the processing of overlong products is guaranteed to be free of jitter, which improves processing efficiency.

Advantages of Double-Knife Wood Lathe With Automatic Loading & Unloading

Single-axis double knives, both use independent drive control, can set the processing depth at will, and can set the processing times according to different materials.

Use multiple combined cylinder structures to run in linkage to achieve fully automatic loading and unloading. Just set it up and start processing with one button, which is easier to operate.

The control system uses international standard G code to run, supports multiple software outputs, has good compatibility, and comes standard with an external pulse handwheel, which makes tool setting more convenient.

The automatic loading and unloading cylinders are all controlled by independent buttons, which is more convenient to use and adjust.

Use 5.5KW high-power three-phase asynchronous motor, fast speed, large torque, and faster processing.

Use CK-1000TC CNC control system, internal integrated macro program, compatible with various CAD, CAM type software, can directly recognize DXF, DBF, TXT, NC format drawings, more convenient to use.

Application Scope of Double-Knife Wood Lathe With Automatic Loading & Unloading

Applicable Materials:

Wood, plastic, acrylic, nylon, PVC, carbon fiber, artificial wood substitutes, etc.

Applicable Industries:

Furniture: table legs, chair legs, sofa legs, bed legs, pool table legs, stair railings, Roman columns, etc.

Musical instruments: piano legs, flutes, suona, bassoons, drumsticks, etc.

Sports: baseball bats, wooden balls, chess, etc.

Other products: wooden handles, wooden bowls, vases, plates, cups, etc.

Double-Knife Wood Lathe With Automatic Loading & Unloading Technical Parameters

| Model | CK-1530-2A |

| Processing Dimensions | 1500 * 300mm (customizable according to processing requirements) |

| Lathe Bed | Heavy-duty integral casting bed, independent anti-interference control cabinet |

| Electrical Machinery | 5.5KW three-phase asynchronous rotating motor |

| Driving Mode | YAKO driver |

| Motor Speed | 0-6000rpm/min |

| Frequency Converter | BEST/Hypmont inverter |

| Transmission Mode | XY axis 25TBI high-precision ball screw transmission, Z axis uses high-precision helical rack/TBI 32 ball screw |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail/25 flange slider |

| Equipment Cable | Pure copper anti bending cable |

| Control System | CatekCNC dedicated control system panel, CK1000TC |

| Loading & Unloading Device | Multi-linked cylinder loading rack (simple and easy to use) |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, solidworks UG powermill, etc. |

| Engraving Instructions | Standard G code, u00,mmg,plt |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1900kg |

| Expanded Size | 3100*2150*1650mm |

Detailed Introduction of Double-Knife Wood Lathe With Automatic Loading & Unloading

Double-Knife Wood Lathe automatic loading part

Optional grinding wheel

Optional protective baffle

Double-Knife Wood Lathe With Automatic Loading & Unloading processing sequence and safety sensor

When preparing for processing, we first need to adjust the machine's loading structure to the size of the wood we need to process. After adjusting the corresponding cylinders, we complete the machine parameter settings, then import the completed drawings into the machine through a U disk, and then perform tool calibration on the machine. After all operations are completed, we click Start Processing, and the machine can start fully automatic processing. When the raw materials in the machine's silo are about to be processed, the machine's infrared sensor switch will automatically detect. If there is not enough wood to continue processing, the machine will automatically pause. After continuing to put materials into the silo, the machine can start automatic processing. The machine's XYZ axes and silos are respectively equipped with infrared sensor switches. During processing, if the machine's processing range exceeds the safety range, the CNC woodworking lathe will automatically pause processing and display an alarm. At this time, you only need to release the alarm and the machine can resume normal processing.

The following are the processable products of Double-Knife Wood Lathe With Automatic Loading & Unloading

| Model | CK-1530-2A |

| Processing Dimensions | 1500 * 300mm (customizable according to processing requirements) |

| Lathe Bed | Heavy-duty integral casting bed, independent anti-interference control cabinet |

| Electrical Machinery | 5.5KW three-phase asynchronous rotating motor |

| Driving Mode | YAKO driver |

| Motor Speed | 0-6000rpm/min |

| Frequency Converter | BEST/Hypmont inverter |

| Transmission Mode | XY axis 25TBI high-precision ball screw transmission, Z axis uses high-precision helical rack/TBI 32 ball screw |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail/25 flange slider |

| Equipment Cable | Pure copper anti bending cable |

| Control System | CatekCNC dedicated control system panel, CK1000TC |

| Loading & Unloading Device | Multi-linked cylinder loading rack (simple and easy to use) |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, solidworks UG powermill, etc. |

| Engraving Instructions | Standard G code, u00,mmg,plt |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1900kg |

| Expanded Size | 3100*2150*1650mm |

REVIEWS

Let more people know what you share.