[Function Description]

Compared with 1530-S, the four-axis linkage single-axis turning, milling and carving CNC wood lathe has added a four-axis linkage function.It can perform turning, punching, grooving, milling, 3D carving and other work on the product shape.

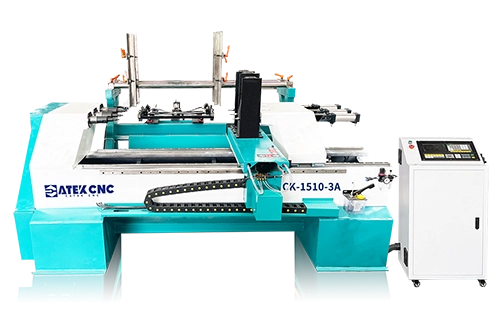

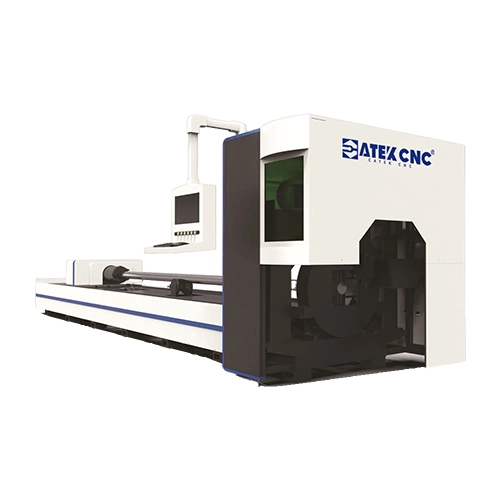

Overview of Single-Axis Multifunctional CNC Wood Lathe With Four-Axis Linkage

The single-axis double-knife turning, milling, carving and flat carving four-axis integrate CNC woodworking lathe is a multifunctional CNC woodworking lathe. It is equipped with a 4KW high-speed rotating servo motor to drive the wood to rotate. The speed mode and position mode can be switched. When turning wood, the speed mode is used. At this time, the machine performs turning processing through high-speed rotation. The position mode is used when milling and carving. At this time, the machine accurately controls the shape of the product through the rotation angle. The high-speed air-cooled spindle speed can reach 18000rpm/min, which can quickly process the wood and make the surface smoother. Through the cooperation of the servo motor and the high-speed air-cooled spindle, slotting, punching, milling, 3D carving, four-axis carving and other functions can be realized, making the machine more widely used and suitable for a variety of processing scenarios. Whether it is a hobby, a personal studio, or a large factory, this CNC woodworking lathe can be used. The design is more user-friendly and the operation is simpler and faster.

Advantages of Single-Axis Multifunctional CNC Wood Lathe With Four-Axis Linkage

Double-tool turning processing can be equipped with various types of CNC turning tools. Different tools can be adapted to different processing products and replaced at will.

The whole machine uses Hiwin guide rails, Hiwin sliders, TBI high-precision ball screws, and fully automatic lubricating oil pots to automatically oil and maintain the machine, making it more durable.

The main motor uses a high-speed servo rotary motor with a maximum speed of 6000r/m, which can support dual-mode switching of speed mode/position mode.

Using a 3.5KW high-speed air-cooled spindle, combined with four-axis four-linkage control, it can process various complex products.

The machine uses a full cast iron bed, which is completed through high-temperature tempering casting and stress relief processing. The weight of the bed alone reaches 1000kg, which is more stable to use and can ensure processing accuracy even after long-term use.

Application Scope of Single-Axis Multifunctional CNC Wood Lathe With Four-Axis Linkage

Single-Axis Multifunctional CNC Wood Lathe With Four-Axis Linkage has a wide range of uses and is suitable for all kinds of products, whether it is wooden furniture, wooden crafts, or other wooden products, it can be used to process wooden stair columns, wooden furniture, sofas, tables, chairs, stools, etc., as well as some wooden crafts, vases, pen holders, etc., and some common sports and music supplies.

Single-Axis Multifunctional CNC Wood Lathe With Four-Axis Linkage Technical Parameters

| Model | CK-1530-4S |

| Processing Dimensions | 1500mm long * 300mm diameter(customizable according to processing requirements) |

| Lathe Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW pure servo rotary motor |

| Motor Speed | 0-6000r/m |

| Driving Mode | Servo drive |

| Frequency Converter | BEST inverter/servo frequency conversion drive |

| Spindle | 3.5KW high-speed air-cooled variable frequency spindle (supports four-axis four-linkage) |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | XY axis 25TBI ball screw drive, Z axis uses high-precision helical rack/TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail/25 slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CatekCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, solidworks UG powermill, etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Expanded Size | 3100*1400*1750mm |

Detailed Introduction of Single-Axis Multifunctional CNC Wood Lathe With Four-Axis Linkage

Spindle with four-axis linkage function

2530-4S (1530-4S customized lengthened version)

1530-4S with grinding wheel

Accessories (optional automatic tool changer)

The following are the processable products of Single-Axis Multifunctional CNC Wood Lathe With Four-Axis Linkage

| Model | CK-1530-4S |

| Processing Dimensions | 1500mm long * 300mm diameter(customizable according to processing requirements) |

| Lathe Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW pure servo rotary motor |

| Motor Speed | 0-6000r/m |

| Driving Mode | Servo drive |

| Frequency Converter | BEST inverter/servo frequency conversion drive |

| Spindle | 3.5KW high-speed air-cooled variable frequency spindle (supports four-axis four-linkage) |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | XY axis 25TBI ball screw drive, Z axis uses high-precision helical rack/TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail/25 slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CatekCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, solidworks UG powermill, etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Expanded Size | 3100*1400*1600mm |

REVIEWS

Let more people know what you share.