[Function Description]

The small 0820 model is a CNC wood lathe designed and manufactured specifically for small factories. This lathe has a small footprint, is easy to operate and has a very high cost-effectiveness.

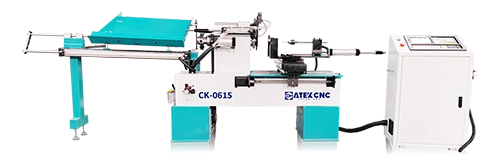

Overview of Small Single-Axis Double-Knife Wood Lathe

The small 0820 model is a CNC wood lathe designed and manufactured specifically for small factories. This lathe has a small footprint, is easy to operate and has a very high cost-effectiveness. The maximum processing size of this machine is 800mm in length and 200mm in diameter. Compared with the ordinary 1530 model CNC wood lathe, it only reduces the processing size, but it has the same performance as the ordinary 1530 model, uses the same motor, control system and drive system, and the processing efficiency is the same as the ordinary 1530 model. We can even customize a small CNC wood lathe with two axes for you, which can be used to process two identical products at a time, and the price is very similar to that of 0820. The small 0820 lathe can bring you a return far beyond its price. It can work continuously 24 hours a day, only one person is needed to load the material, and the processing can be started by clicking the start button. It changes the traditional woodworking method of processing with hand tools, saves the trouble of time-consuming and laborious processing, completes the processing in one step, improves the processing efficiency, and only needs to import the drawings into the machine to start processing, and the processed products are exactly the same and more standardized.

Advantages of Small Single-Axis Double-Knife Wood Lathe

Single-axis double-knife processing is more suitable for processing small products. It is also equipped with a knife sheath bracket, which can also easily process slender products.

This small machine also uses a full cast iron bed, which is processed by five-sided gantry milling and the guide rail groove is processed in one go to ensure the machine processing accuracy.

The main motor uses a 4KW high-torque high-speed motor and is equipped with an independent frequency converter. The speed can be adjusted at will within 6000 rpm, making it more convenient to use.

It uses the same dedicated CK1000TC control system as other machines, recognizes standard G codes, and is compatible with all types of CAD and CAM type software.

Use Morse ejector pin and four-jaw chuck to fix the material for processing, stable processing and high efficiency.

Interchangeable chucks and inner hole cutters for processing wooden bowls, vases, plates, flower pots, etc.

Application Scope of Small Single-Axis Double-Knife Wood Lathe

Applicable Materials:

Wood, plastic, acrylic, nylon, PVC, carbon fiber, artificial wood substitutes, etc.

Applicable Industries:

Furniture: table legs, chair legs, sofa legs, bed legs, pool table legs, stair railings, Roman columns, etc.

Musical instruments: piano legs, flutes, suona, bassoons, drumsticks, etc.

Sports: baseball bats, wooden balls, chess, etc.

Other products: wooden handles, wooden bowls, vases, plates, cups, etc.

Small Single-Axis Double-Knife Wood Lathe Technical Parameters

| Model | CK-0820 |

| Processing Dimensions | 800 * 200mm (customizable according to processing requirements) |

| Lathe Bed | Heavy-duty integral casting bed, independent control cabinet |

| Motor | 4KW three-phase asynchronous motor |

| Motor Speed | 0-6000r/m |

| Driving Mode | YAKO driver |

| Frequency Converter | BEST/Hypmont inverter |

| Transmission Mode | XY axis 25TBI high-precision ball screw transmission, Z axis uses high-precision helical rack/TBI 32 ball screw |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail/25 flange slider |

| Equipment Cable | Pure copper high-flexible bending-resistant cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, solidworks UG powermill, etc. |

| Engraving Instructions | Standard G code, u00,mmg,plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1100kg |

| Expanded Size | 2300*1200*1300mm |

The following are the processable products of Small Single-Axis Double-Knife Wood Lathe

The use of small CNC wood lathe

The small CNC wood lathe is very simple to use. After receiving the machine, you need to connect the machine to the power supply according to the instructions. After the power is connected, we need to test whether the functions of each axis are normal. After all the preparations are completed, we will draw the drawings we need to use through the drawing software, copy them to the machine through the U disk, and then use the machine to calibrate the tool. After the tool adjustment is completed, the machine can start normal processing. After the daily processing is completed, we need to clean and maintain the machine.

| Model | CK-0820 |

| Processing Dimensions | 800 * 200mm (customizable according to processing requirements) |

| Lathe Bed | Heavy-duty integral casting bed, independent control cabinet |

| Motor | 4KW three-phase asynchronous motor |

| Motor Speed | 0-6000r/m |

| Driving Mode | YAKO driver |

| Frequency Converter | BEST/Hypmont inverter |

| Transmission Mode | XY axis 25TBI high-precision ball screw transmission, Z axis uses high-precision helical rack/TBI 32 ball screw |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail/25 flange slider |

| Equipment Cable | Pure copper high-flexible bending-resistant cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, solidworks UG powermill, etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1100kg |

| Expanded Size | 2300*1200*1300mm |

REVIEWS

Let more people know what you share.

To be honest, I don't have a lot of money. I spent a long time looking for the right machine and my father finally gave me the go-ahead to buy this one. Buying a machine from another country is risky, so I was lucky to find the perfect one.