Blog list

What are the types of laser cutting machines?

- 12 / 05 / 2024

Laser cutting uses laser instead of physical cutting tools or high-temperature flame cutting. Due to the characteristics of laser, it has significant advantages over traditional cutting.In addition to the power of laser cutting, the optical properties of the laser have the greatest impact on cutting,Such as wavelength, pulse width, pulse repetition frequency, etc.Depending on the type of laser, the current industrial laser equipment is mainly divided into fiber laser, CO2 laser and YAG laser.

Fiber Laser

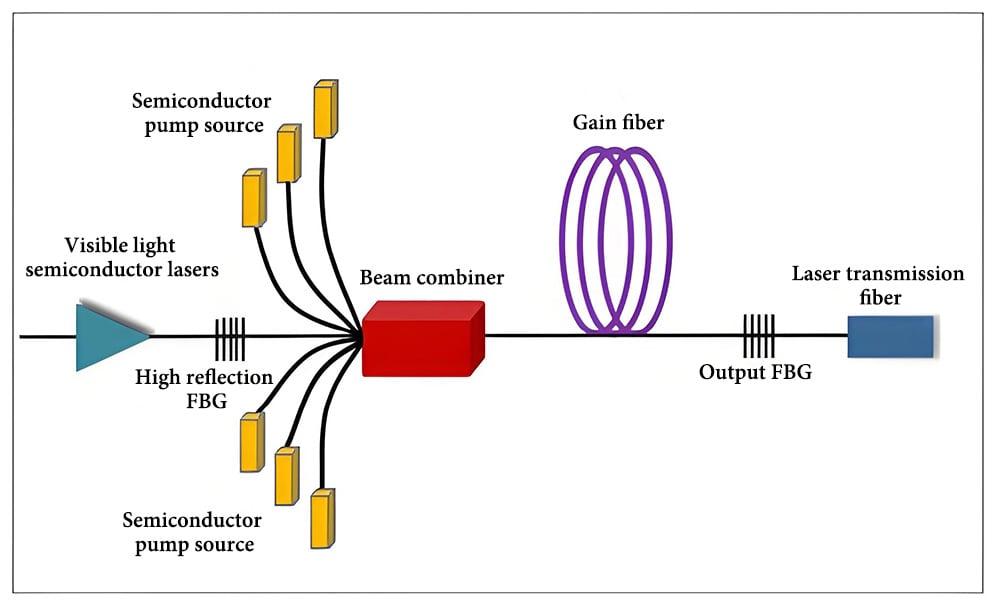

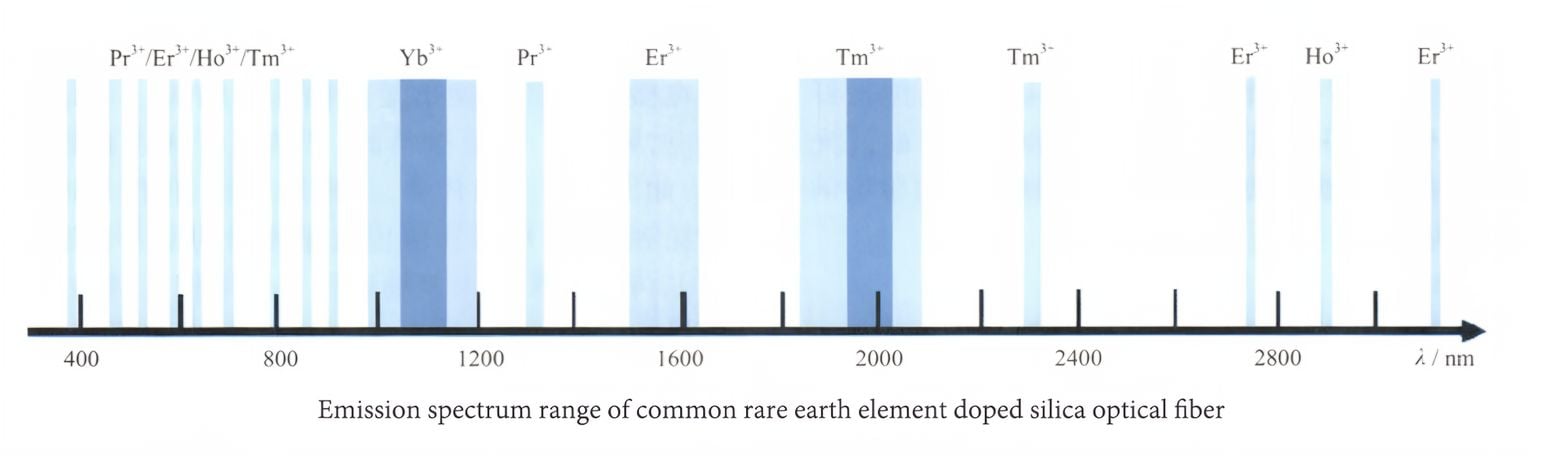

Fiber laser is a kind of laser system that uses glass fiber doped with rare earth elements as gain medium. It consists of three parts: gain medium, pump source and resonant cavity. Generally, semiconductor laser is used as pump source, and resonant cavity is generally composed of reflector, fiber end face, fiber ring mirror or fiber grating and other devices. Active fiber with rare earth elements (erbium (Er3+), ytterbium (Yb3+), neodymium (Nd3+), samarium (Sm 3+), thulium (Tm3+), holmium (Ho3+), praseodymium (Pr3+), dysprosium (Dy3+), bismuth (Bi3+), etc.)) is used as gain medium.

Depending on the doped ions, fiber lasers can achieve laser outputs of different wavelengths. The wavelength used in industry is generally 1.06um (one tenth of the wavelength of CO2 laser), so it is particularly suitable for cutting thin metal plates.

Advantages of fiber lasers

Good beam quality: The waveguide structure of the optical fiber determines that the fiber laser is easy to obtain single transverse mode output, and is less affected by external factors, and can achieve high-brightness laser output.Using this type of laser has a small straight-edge cut and a smooth cut surface, and can obtain a large depth-to-diameter ratio and depth-to-width ratio.

High photoelectric conversion efficiency: The electro-optical conversion efficiency can reach 20%~30% (CO2 lasers are generally 8%~10%). The extremely high energy conversion efficiency makes this type of laser more energy-saving and generates less heat. Low-power equipment can use an air-cooling system, and the power requirements of the water-cooling machine used in high-power equipment are also reduced accordingly.

High cutting speed: The cutting speed can reach 4~5 times that of YAG laser cutting machine.

High equipment stability and simple maintenance:The optical path is simple, no complicated reflectors are required, it is less affected by the external environment, and the subsequent maintenance cost is low.

Low cost of use: The extremely high electro-optical conversion efficiency can save more electricity, the simple optical path system makes the subsequent maintenance cost very low, and no gas medium is used, saving related costs.

Harmless to human body: Laser wavelength is infrared light that is invisible to the human eye and poses no harm to the human body.

Disadvantages of fiber lasers

Cutting material limitation: Fiber laser cannot cut non-metallic materials, nor can it cut materials with a coating on the surface, such as ordinary coated stainless steel, special steel plates with anti-rust coating, etc.

High initial cost: The initial purchase of a fiber laser cutting machine is higher, but the subsequent operating costs are much lower.

CO2 Laser

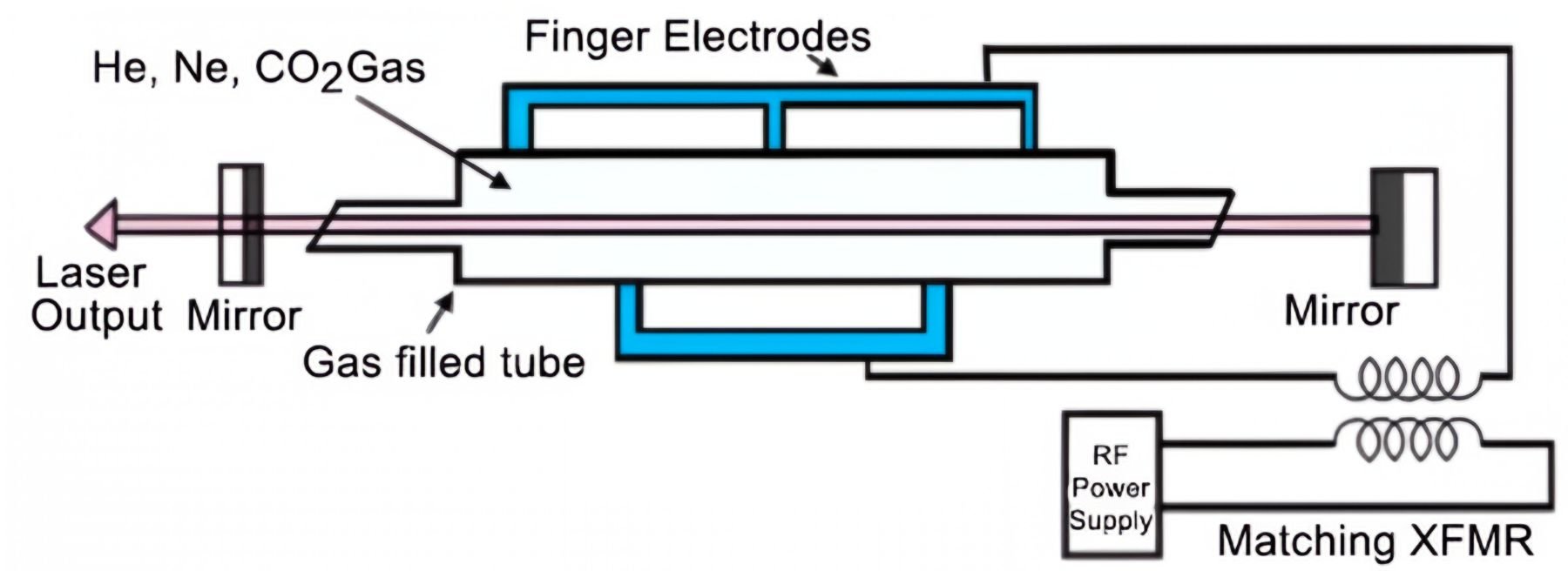

CO2 laser is a gas laser, which is the representative of "vibration-rotation molecular laser" in gas laser. Its working gas is a mixture of CO2, N₂ and He. The electrons in the atoms remain in the ground state, and the laser transition occurs between two rotational energy levels of different vibration states of CO2.

The laser generating component of CO2 laser cutting machine is CO2 laser tube. The light is reflected many times on the reflector in the laser, and is repeatedly amplified by the resonant cavity, and finally focused into a beam of high-energy laser for cutting the processed object.

Advantages of CO2 laser

Cutting of non-metallic materials: CO2 laser has a wavelength of 10.6μm. The light beam of this wavelength is easily absorbed by non-metallic materials. Its low reflectivity and evaporation temperature make the absorbed light energy almost completely enter the material, and cause evaporation to form holes in an instant, entering a virtuous cycle during the cutting process.

Stable performance: CO2 laser cutting machines have been used for more than 30 years. Many of its processing characteristics have been thoroughly studied and the processing technology has become very mature.

Harmless to human body: Laser wavelength is infrared light that is invisible to the human eye and poses no harm to the human body.

Disadvantages of CO2 laser

Not suitable for metal cutting: Ordinary CO2 laser cutting machines are difficult to cut metal materials because the 10.6 micron wavelength optical fiber emitted by them is difficult for metal materials to absorb. Although some metal cutting can be achieved by modifying the cutting machine (increasing power, adding reflective isolator, using oxygen combustion, etc.), the cost and cutting effect are far inferior to the fiber laser cutting machine, and the cutting ability of high reflectivity metal materials is very poor, especially not suitable for processing high reflectivity non-ferrous metals such as gold, silver, copper, aluminum, zinc, etc.

High cost of later use: The 10.6μm laser generated by CO2 laser cutting machine cannot be transmitted through optical fiber, and requires multiple reflectors for reflection. The optical path is complicated. Once installed, it is not easy to move. It has strict requirements on the environment. Vibration, dust, light, etc. all affect its stability of use.And the power consumption is high, and the service life of the reflector and gas consumption also increase its use cost.

Low degree of processing flexibility: Compared with the optical fiber light guide of fiber laser, this type of laser processing flexibility is low. How to increase the 3D cutting range of CO2 laser cutting machine has always been a difficult problem in the industry.

YAG Laser

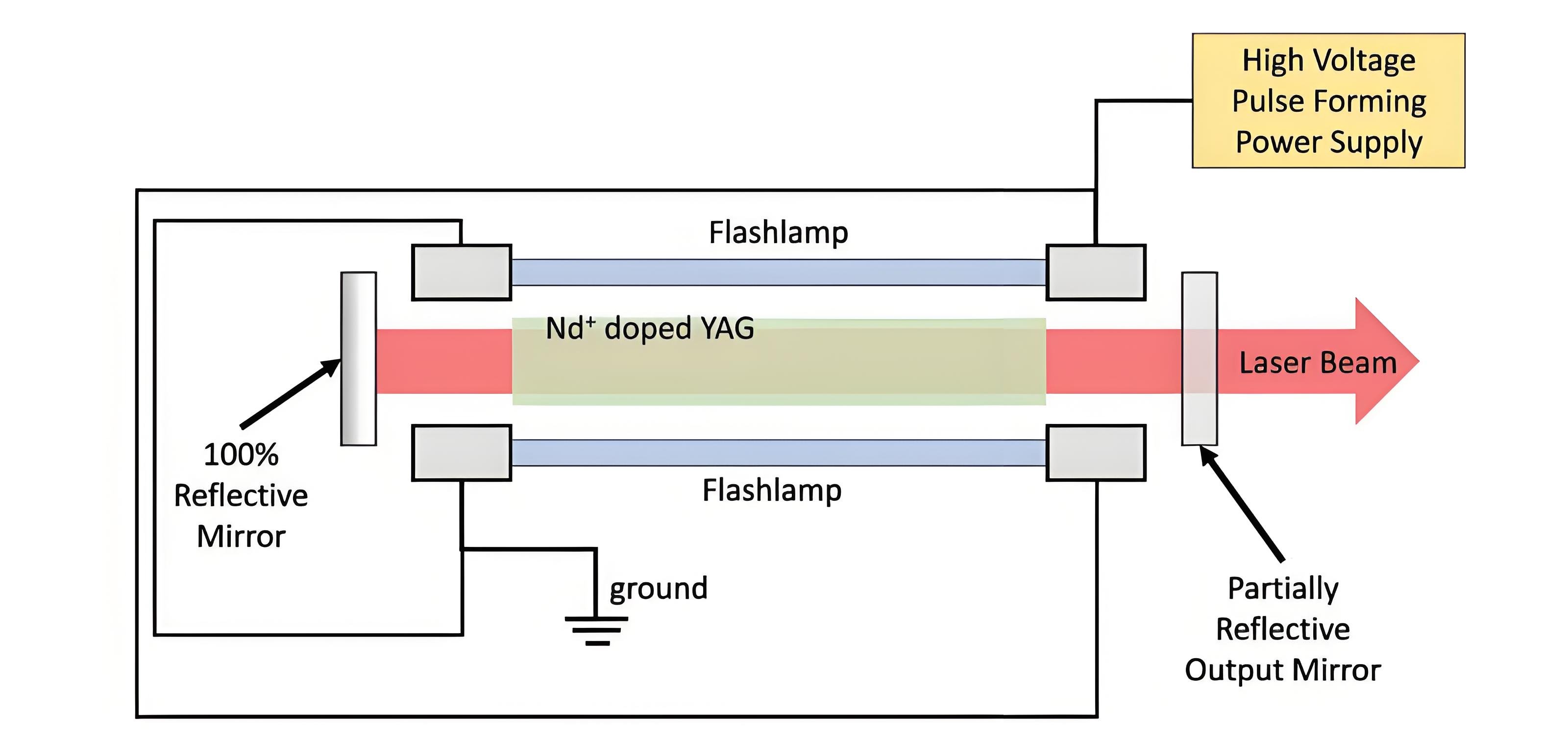

YAG laser, the full name of which is neodymium-doped yttrium aluminum garnet laser, is a solid laser based on yttrium aluminum garnet crystal (Y3Al5O12, referred to as YAG).

Advantages of YAG lasers

High single pulse energy and high peak power: YAG crystal has a high damage threshold, which can achieve large single pulse energy and high peak power. In some processing applications that require instantaneous high energy output, such as drilling and deep engraving of certain materials, YAG laser can complete the processing tasks more effectively, and its application range is relatively wider.

Strong metal material processing capability: It produces lasers with a wavelength of 1.06μm, with high coupling efficiency with metals and good processing performance.

High processing flexibility: YAG lasers can be coupled with optical fibers, and have extremely high processing flexibility like optical fiber lasers.

Low price: YAG lasers are a relatively mature laser with high technical maturity, relatively cheap prices, and low initial investment costs.

Harmless to human body: Laser wavelength is infrared light that is invisible to the human eye and poses no harm to the human body.

Disadvantages of YAG lasers

Low electro-optical conversion efficiency: The electro-optical conversion efficiency of YAG lasers is generally 1% to 3%, and most of the electrical energy is converted into thermal energy.

Obvious thermal effect: When the YAG laser is working, a temperature gradient will be generated inside the laser rod, causing thermal stress and thermal lens effect. Thermal stress may cause the laser rod to break, affecting the normal operation of the laser; the thermal lens effect will change the focusing characteristics of the laser beam, reduce the beam quality, and limit its average power and beam quality improvement. Fiber lasers use slender rare earth-doped optical fibers as gain media, which have a large surface area to volume ratio and fast heat dissipation, and can effectively avoid the problem of reduced beam quality and efficiency caused by thermal effects.

Poor non-metal cutting ability: Like fiber lasers, YAG's 1.06μm wavelength laser is also not suitable for cutting non-metal materials.

Purchase suggestions

If you mainly process metal materials, fiber laser is a good choice. It is particularly suitable for cutting metal sheets. The electro-optical conversion efficiency is also much higher than that of CO2 laser and YAG laser. It is small in size and easy to maintain. It has excellent flexible processing capabilities. In particular, the cost of fiber laser cutting machines has gradually decreased in recent years. It has almost replaced traditional solid lasers and carbon dioxide lasers in metal cutting.

If you mainly process non-metallic materials (such as wood, acrylic, plastic, leather, ceramics, etc.), then carbon dioxide laser is the only choice.

In addition to its obvious cost advantage, YAG lasers have been basically replaced by fiber lasers in the field of industrial cutting.

RELATED MODELS

We recommend some related models for you...

The mini CNC router is specially prepared for small DIY studios and amateurs. It has the advantages of small footprint, low power consumption, low noise, simple operation and low price. It is more suitable for use in small studios.

$1,400.00~$2,570.00

Plasma cutter is a metal cutting machine. When cutting metal of small thickness, the cutting speed is extremely fast, and the cutting surface is smooth, the thermal deformation is small, and there is almost no heat-affected zone.

$3,380.00~$5,600.00

Suitable for marking large, difficult-to-move products. Select the location and mark with one button. Portable and handheld, all-aluminum alloy head, weighing only 3 kg, compact and portable, easy to operate with one hand, positioning, distance bracket is adjustable, detachable, and suitable for a variety of ranges.