Blog list

How to choose the milling cutter for CNC wood router?

- 10 / 30 / 2024

The milling cutter for CNC wood router is mainly selected from the following aspects:

Determine the main technical parameters of the milling cutter: tool outer diameter, processing thickness, center hole diameter Other technical parameters: number of teeth, rotation direction, rotation speed, feed speed, clamping method, tooth material.

Select the structural form of the milling cutter: According to the nature and requirements of the cutting object, comprehensively consider the selection of integral milling cutter, welded integral milling cutter, assembled milling cutter and combined milling cutter from both technical and economic aspects.

Selection of the rotation direction of the milling cutter: The rotation direction of the milling cutter is determined according to the rotation direction of the main shaft of the processing machinery and the relative position of the cutter shaft and the feed workpiece. Whether it is an integral milling cutter or an assembled milling cutter, the inclination angle of the cutting blade relative to the milling cutter radius determines the rotation direction of the milling cutter.

Selection of the cutting amount of the milling cutter: The cutting amount of the milling cutter includes the cutting speed of the milling cutter, the feed speed of the workpiece and the milling depth. The cutting speed of the milling cutter depends on the milling cutter speed and the radius of the milling cutter. The feed speed of the workpiece depends on the requirements for the surface quality of the cutting process. The surface roughness of the workpiece being cut depends largely on the feed amount per tooth of the milling cutter during the cutting process. If the feed amount per tooth is too large, the machined surface will be too rough. If the feed amount per tooth is too small, the machined surface will be burned. Therefore, the feed amount per tooth of the milling cutter must be appropriate.

Stability of milling cutter operation: The stability of milling cutter operation is the basis for ensuring machining accuracy and machining surface quality. This includes two aspects: one is that the milling cutter vibrates due to external force during cutting; the other is that the milling cutter deforms under the action of external force.

Safety of milling cutter processing: The safety of milling cutter processing includes milling cutter rotation speed limit, chip thickness limit, forming milling cutter profile height limit and assembly milling cutter blade thickness and extension limit.

The characteristic of wood cutting is high-speed cutting. The rotation speed of the milling cutter is mostly above 3000rpm. High-speed cutting brings high production efficiency and smooth surface quality to wood cutting. At the same time, it also brings a series of safety issues. Therefore, when the spindle speed of the milling machine reaches 9000rpm, except for the shank milling cutter with a tool less than 16mm, the use of assembled milling cutters should be prohibited, and the welds of the welded integral milling cutters should also be strictly inspected for flaws. The chip thickness limit is a necessary measure to ensure that the milling cutter feed is too large and causes serious overload of the milling cutter.

For the forming milling cutter, the profile height value of the forming profile is closely related to the clamping method of the milling cutter, the thickness of the cutting workpiece, and the diameter of the milling cutter. After the thickness of the cutting workpiece, the diameter of the milling cutter and the center hole diameter are determined, the profile height of the milling cutter reflects the strength and rigidity of the milling cutter itself, as well as its ability to withstand cutting resistance. Therefore, the profile height must be limited to ensure the safety of the milling cutter when in use. The clamping problem of the blade must be considered when designing the assembled milling cutter body. Whether it is a cylindrical cutter body or a disc-shaped cutter body, the blade clamping form must ensure that it can provide a sufficiently large clamping force to resist the rotating centrifugal force.

RELATED MODELS

We recommend some related models for you...

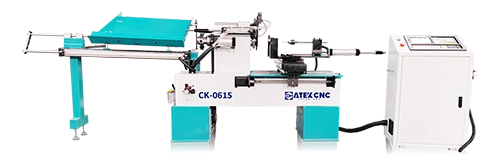

This small lathe is specially designed for processing various small handicrafts, toys, chess, etc. It has complete functions and automatic feeding function, which can realize fully automatic processing of small products.

$3,600.00~$5,150.00

The CNC Router With Vibration Knife adds a vibration knife to the ordinary 1325, which enables it to carve hard materials while increasing the ability to cut flexible materials, making it more widely used.

$3,800.00~$4,500.00

The five-axis woodworking machining center is a high-end CNC machine with five independent motion axes, including three linear axes (X, Y, Z) and two rotary axes (A and C). This unique structure enables the five-axis machining center to achieve precise cutting and processing of all surfaces of the workpiece through the linkage control of the five axes in one clamping.