Blog list

Comparison between CNC wood lathes and manual lathes

- 12 / 03 / 2024

Traditional Woodworking

Before the emergence of woodworking lathes, humans have always processed various types of wood products by hand.

Traditional manual processing has a long history, and the various processing techniques and tools related to it have also been refined and developed in the long history. It represents the essence of human wisdom and craftsmanship. It is not only a skill, but also a cultural and historical heritage.

With the progress of human civilization, manual woodworking processing is gradually disappearing, but many people still love handmade wood products, thinking that they have deeper personal connections and emotional value, and can appreciate the ingenuity of the maker, while the wood products processed by cold machines cannot convey this emotion.

Handmade wood products can be designed in a more personalized way and are extremely flexible. Although good machines have gradually become comparable to manual work in this regard, they still require complicated program design and are easily restricted during the processing process.

Compared with mechanical processing, handmade wood products are usually able to handle details better and more flexibly. Although modern mechanical technology is mature enough and is still developing, when it comes to the processing of some complex parts, manual secondary processing is still required after the machine is processed.

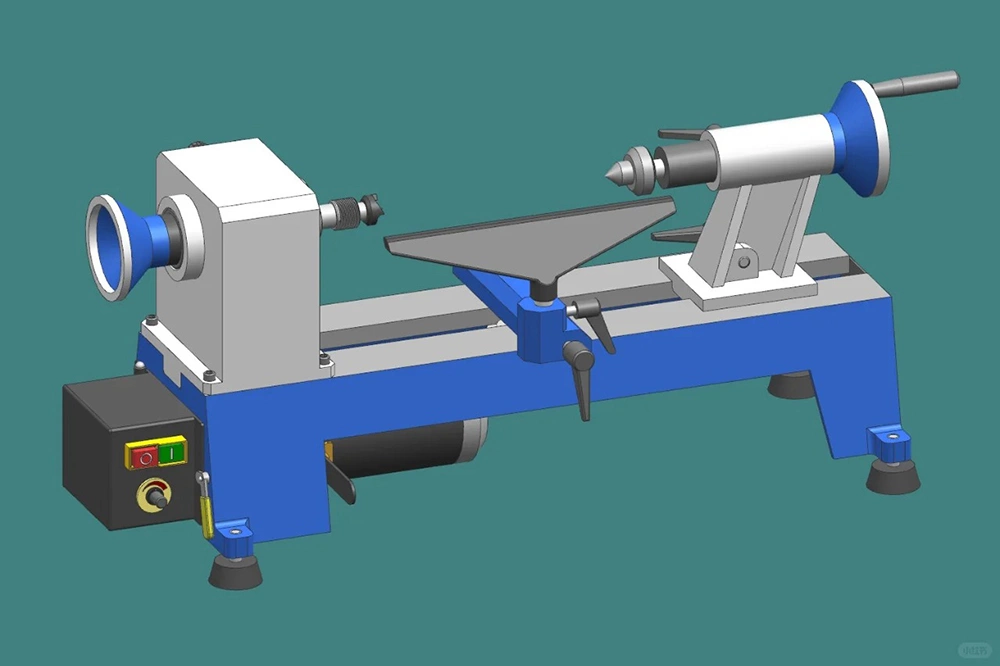

Manual Lathe

With the development of the times, in the 1980s, Maudsley, a British inventor and inventor of modern lathes, made a modern lathe with a screw-driven tool holder. After decades of development and improvement, turret lathes and return wheel lathes were invented in the United States. In the early 20th century, lathes with gear transmissions driven by a single motor appeared. In the 1940s, lathes with hydraulic profiling devices were promoted. At the same time, multi-tool lathes were also developed.

The above lathes are not very automated, and they still need to be operated manually. During processing, mechanical tools are shaken by hand to cut wood, and the accuracy of products is measured by eyes with tools such as calipers. At this time, although humans are freed from heavy processing operations to a certain extent and production efficiency is increased, the operation of machine tools still requires a large number of experienced workers, and the processed products are still affected by the operator's level. In addition, due to the high participation of humans in the processing process, various tools of the machine are easy to cause danger to the operator, and processing dust also harms the operator's health.

At present, manual lathes are still widely used all over the world, but are gradually being replaced by CNC lathes.

CNC Lathe

In the 1990s, with the advancement of control systems and the advent of computers, human society has undergone earth-shaking changes, and the machinery industry has also been affected.

In 1952, the first CNC machine tool came out, becoming an epoch-making event in the history of the world's machinery industry and promoting the development of automation.

CNC technology is also called computer numerical control technology (CNC, Computerized Numerical Control), which is a technology that uses computers to implement digital program control. This technology uses computers to perform the motion trajectory of the equipment and the operation timing logic control function of the peripherals according to the control program stored in advance. Since the computer is used to replace the CNC device originally composed of hardware logic circuits, the storage, processing, calculation, logical judgment and other control functions of the input operation instructions can be completed by computer software, and the microscopic instructions generated by the processing are transmitted to the servo drive device to drive the motor or hydraulic actuator to drive the equipment to operate.

In terms of processing technology and processing surface formation method, it is basically the same as ordinary machine tools. The most fundamental difference between the two lies in the principle and method of realizing automatic control. CNC machine tools use digital information to achieve automatic control. The information related to the processed parts: the dimensional parameters of the relative motion trajectory between the workpiece and the tool (such as feed rate), the process parameters of the cutting process (such as the speed of the main motion and feed motion, the amount of back cutting, etc.) and various auxiliary operations (main motion speed change, tool replacement, cutting fluid start and stop, and workpiece clamping and loosening, etc.) are written into a processing program in a certain format using a code composed of specified words, numbers and symbols. The processing program is then input into the CNC device, which, after analysis and processing, sends out various signals and instructions corresponding to the program to control the machine tool for automatic processing. The principle and process of this digital control are completed through the various components of the above-mentioned CNC machine tools.

The biggest difference between CNC machine tools and traditional machine tools is that the entire processing process is controlled by machines, which completely liberates manpower. Since all measurements, decisions, controls, transmissions, and processing are controlled by programs, the processing consistency is good and the processing accuracy is very high (CatekCNC's woodworking lathe repeat positioning accuracy can reach ±0.02 mm).

However, CNC machine tools are not without shortcomings. For example, they are not as flexible and applicable as ordinary manual lathes. However, it is impossible for one machine to process all products. CNC machine tools crush manual lathes in specialization, automation, processing efficiency and precision. CNC machine tools are more suitable than manual lathes in processing standard parts and mass production. In order to solve these problems, CatekCNC has developed a variety of different models of woodworking lathes. The 1530-T series lathes with multiple function switches can maximize the functions of a single lathe. As an old OEM, we can also customize the machine size, function, appearance, etc. according to your any needs. If you have doubts about the type of product to be processed by a certain machine, we can also perform sample trial processing according to your requirements. You don’t even need to go out. We can complete this remote video. Of course, if you want to visit our factory on site, we are always welcome and try to arrange relevant matters for you. Due to the complexity of CNC lathes themselves and overseas transportation, we strongly recommend that you contact our sales staff, who will give you professional advice.

The price of CNC machine tools is also more expensive than traditional manual lathes. This is determined by the cost of the machine tools. As an OEM factory, we can guarantee that you can get the source price.

In addition, CNC machine tools are more complicated to maintain than ordinary manual lathes, and the later maintenance costs are higher. Our electrical components are all purchased from world-renowned brands, and the bed is made of cast iron. The product quality is guaranteed from the beginning of the raw materials. The warranty period of our machine is 3 years. During the warranty period, if the accessories are damaged due to the machine itself, the accessories will be replaced free of charge (except for wearing parts). If the machine has a major failure and you cannot solve it through remote guidance, although it is overseas trade, our technicians have many overseas experiences, and they can also repair it on site for you.

Although CNC machine tools liberate manpower, they require CNC programming. We have a full set of training materials and sample drawing codes, etc., and can guide you to process through remote guidance. If you need it, we also have on-site training business for technicians. Long-term domestic trade has allowed us to accumulate a large number of training methods for customers of different levels, so you don’t have to worry about not being able to learn how to operate.

RELATED MODELS

We recommend some related models for you...

The new heavy-duty double-axis four-knife CNC wood lathe is a CNC wood lathe that is more suitable for small processing plants. This CNC wood lathe is easy to operate, has a fast processing speed, and is cheap. You can get this lathe for only $5,000. This lathe can process two pieces of wood at a time, and four knives are fed in at the same time, which is suitable for batch processing of the same products.

$4,400.00~$5,400.00

The MOPA color laser marking machine is an advanced laser marking equipment that uses MOPA (Master Oscillator Power Amplifier) technology and has significant technical advantages and a wide range of application scenarios.

$3,200.00~$4,900.00

5x10-Foot Plasma Cutter For Sheet & Tube can not only cut plates, but also tubes. This machine has multiple functions and advantages in cutting tubes, and is suitable for cutting various metal tubes. It can realize the functions of short section, cutting, opening and through-line cutting of tubes, etc. It is flexible and simple to operate, and can meet the needs of different industrial production applications.