Blog list

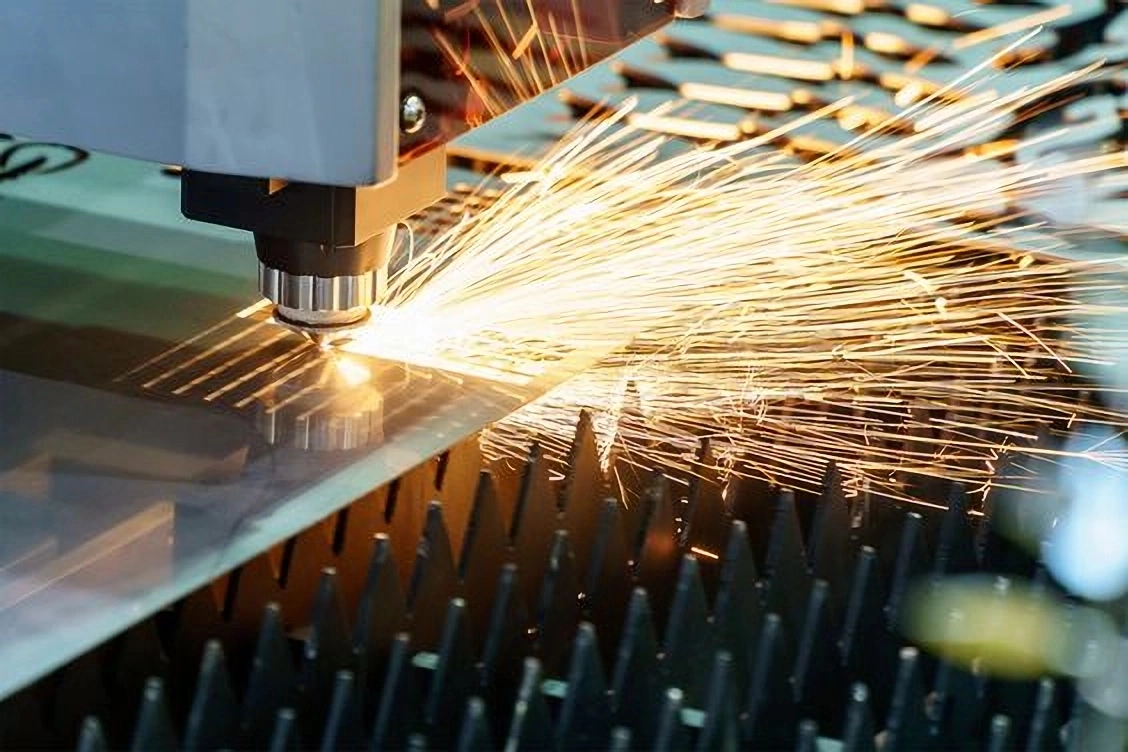

What factors affect the cutting speed of fiber laser cutting machine?

- 10 / 30 / 2024

What is the cutting speed of fiber laser cutter with different powers?

The maximum cutting speed of 500W fiber laser cutting machine for different materials: carbon steel maximum speed 13m/min; stainless steel material maximum speed 13m/min; aluminum plate material maximum speed 5.5m/min; copper plate material maximum speed 5.5m/min ;

The maximum speed of 1000W fiber laser cutting machine for cutting different materials: the maximum speed of carbon steel material is 24m/min; the maximum speed of stainless steel material is 24m/min; the maximum speed of aluminum plate material is 10m/min; the maximum speed of copper plate material is 10m/min ;

The maximum speed of 2000W fiber laser cutting machine for cutting different materials: carbon steel maximum speed 28m/min; stainless steel material maximum speed 28m/min; aluminum plate material maximum speed 25m/min; copper plate material maximum speed 16m/min;

The maximum speed of 3000W fiber laser cutting machine for cutting different materials: the maximum speed of carbon steel material is 35m/min; the maximum speed of stainless steel material is 35m/min; the maximum speed of aluminum plate material is 43m/min; the maximum speed of copper plate material is 35m/min.

What factors are related to the cutting speed of the fiber laser cutter?

For a given laser power density and material, the cutting speed conforms to an empirical formula. As long as it is above the threshold, the cutting speed of the material is proportional to the laser power density, that is, increasing the power density can increase the cutting speed. The cutting speed is inversely proportional to the density (specific gravity) and thickness of the material being cut. PS: The power density referred to here is not only related to the laser output power, but also to the beam quality mode. In addition, the characteristics of the beam focusing system, that is, the size of the spot after focusing, also have a great influence on laser cutting.

The influence of cutting speed of fiber laser cutter on quality

When the cutting speed is too low, since the cutting point is the anode of the plasma arc, in order to maintain the stability of the arc itself, the anode spot or anode area must find a place to conduct current near the slit closest to the arc, and at the same time, it will transfer more heat to the radial direction of the jet, thus making the incision wider. The molten material on both sides of the incision gathers and solidifies at the bottom edge, forming slag that is difficult to clean, and the upper edge of the incision forms a rounded corner due to excessive heating and melting.

Properly increasing the cutting speed can improve the incision quality, that is, the incision becomes slightly narrower, the incision surface is smoother, and deformation can be reduced.

Too fast a cutting speed makes the cutting line energy lower than the required value, and the jet in the slit cannot quickly blow away the molten cutting melt immediately, forming a large amount of drag, accompanied by incision slag, and the surface quality of the incision decreases.

How to increase the cutting speed of fiber laser cutter?

Increase power (within a certain range, such as 500-2000W);

Improve beam mode (such as from high-order mode to low-order mode until TEM00);

Reduce the focused spot size (such as using a short focal length lens to focus);

Cutting materials with low initial evaporation energy (such as plastics, plexiglass, etc.), low-density materials (such as white pine, etc.), and thin materials.

RELATED MODELS

We recommend some related models for you...

Three-Axis Wood Lathe For Pool Cue With Automatic Loading & Unloading is specially designed for processing slender products such as billiard cues. The machine has automatic loading and unloading functions, which can realize unattended fully automatic operation.It can produce three pool cues at a time.

$7,058.00~$8,200.00

The double-knife 1530 lathe has a stable structure, simple operation and low price. It is more suitable for traditional woodworking work, start-up workers and personal studios.

$4,098.00~$5,200.00

Suitable for marking large, difficult-to-move products. Select the location and mark with one button. Portable and handheld, all-aluminum alloy head, weighing only 3 kg, compact and portable, easy to operate with one hand, positioning, distance bracket is adjustable, detachable, and suitable for a variety of ranges.