[Function Description]

ATC CNC Router is a new CNC router machine equipped with straight automatic tool changing function.

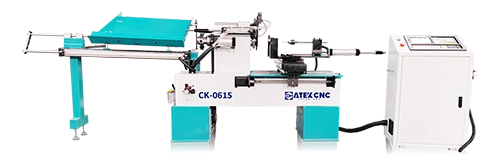

Overview of Straight ATC CNC Router

ATC CNC Router is a new CNC router machine equipped with straight automatic tool changing function. This router machine can eliminate the trouble of manual tool changing. Automatic tool changing is generally equipped with 8 knives, 12 knives, 16 knives, etc. The tool magazine can accommodate tools of different shapes. When processing products with complex shapes, the machine can identify the processing drawings and automatically change the tools according to the shape of the product. The tool magazine can be equipped with various tools such as engraving knives, round bottom knives, cutting knives, milling knives, etc. There is no need for manual operation during processing, and the tools are automatically replaced. The machines all use servo motors with the advantages of high moving speed, high processing accuracy, low noise, etc. At the same time, they are equipped with Shimpo reducers imported from Japan with high positioning accuracy and fast moving speed. During processing, the processing efficiency can be greatly improved and labor can be saved. The ATC CNC router has the functions of engraving, cutting, punching, grooving, 3D engraving, etc., which can meet various processing needs.

Advantages of Straight ATC CNC Router

Use 9kw fully automatic tool change air-cooled spindle, the maximum speed can reach 24000r/m, can quickly process all kinds of plates, with large torque and large feed volume.

With 8/12/16 tool change magazines, tools can be replaced automatically, and automatic tool change can be achieved for different processing needs. With simple settings, complex processes can be completed at one time.

Use 11KW water ring vacuum pump, with 6-zone 24-hole vacuum adsorption table, each zone can be controlled separately. Regardless of the size of the plate, it can be adsorbed and fixed with one button.

Use Taiwan LNC CNC router machine dedicated system, with more expansion functions, humanized design and simple operation.

XY axis uses high-power servo motor drive, with high-precision planetary gear reducer, Z axis uses brake drive brake motor, with higher precision.

Use high-quality Schneider/Delixi electric components, each part is equipped with independent filter, with stronger anti-interference ability and more stable use.

Equipped with 3KW double-tube independent vacuum cleaner, spindle vacuum pipe and material pusher flat suction device, the platform can achieve dust-free environment after each processing.

Using the fully automatic tool setting instrument, regardless of the size of the tool, one-button tool setting operation can be achieved, eliminating the trouble of tool setting after each tool change, and it is easier to use.

The heavy-duty thickened double-layer bed is more stable after high-temperature treatment. It uses a five-sided gantry milling machine for processing, which is more stable to use and has higher processing accuracy.

Application Scope of Straight ATC CNC Router

Applicable Materials:

Suitable for wood boards, density boards, artificial boards, particle boards, gypsum boards, multilayer boards, plastics, PVC, PCB, acrylic, Chevron boards, PTFE boards, aluminum-plastic boards, aluminum, copper and other types of boards.

Applicable Industries:

It can process solid wood furniture, panel furniture, whole house customization, plate carving, hollowing, PVC cutting, PCB cutting, advertising word cutting, LOGO cutting, crystal word cutting, cabinets, office desks, beds, cat climbing frames, bookshelves and other products.

Straight ATC CNC Router Technical Parameters

| Model | CK-1325-T |

| XYZ Work Schedule | 1300*2500*200mm(customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, reinforced steel beams |

| Lathe Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Spindle | HQD 9KW high power air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/m |

| Driving Mode | High torque 1.5KW pure servo motor drive * 4 (Z axis uses brake motor) |

| Reducer | Japan Shimpo reducer |

| Tool Change Magazine | 8/12/16 straight tool magazine |

| Table | Double-layer vacuum table with 6 partitions and 24 wells |

| Vacuum Pump | 11KW water ring vacuum pump |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan high precision 30 linear square rail/30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW Double-barrel Bag Vacuum Cleaner |

| Control System | Taiwan LNC cutting machine dedicated control system |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, JDpaint, etc. |

| Engraving Instructions | Standard G code |

| Positioning | 4+2 Positioning Cylinder |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Processing Speed | 28000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 2900kg |

| Expanded Size | 3900*2100*2100mm |

Optional Accessories for Straight ATC CNC Router

| Spindle | Italian HSD spindle/Italian HITECO spindle |

| Servo Motor | Yaskawa servo motor/Delta servo motor |

| Control System | Syntec/NCStudio/Mach3 etc. |

| Vacuum Pump | Vortex air pump/rotary vane vacuum pump |

| Saw Blades | 6KW saw knife spindle |

| Pressure Roller | Double rod independent pneumatic pressure rollers can be individually controlled to fix the plate |

| Tool Changing Method | Disc tool changer (6/8/10/12) |

| Pneumatic Drill Bits | 5+4 drill bit magazine |

| Automatic Feeding | Automatic lifting loading platform |

| Automatic Unloading | Rolling automatic unloading platform |

| Rotation Axis | 3D engraving fourth axis rotation axis |

| Vibrating Knife | Oscillating knife for cutting paper/leather/foam/cloth etc |

| Camera | CCD camera for scanning, printing and cutting |

Detailed Introduction of Straight ATC CNC Router

9KW automatic tool changing spindle

Automatic tool changer

High power servo motor

Vacuum Pump

Automatic tool setting instrument

4+2 positioning cylinder

Vacuum adsorption table

Taiwan LNC control system interface

Pulse handwheel

Wired pulse handwheel

Wireless pulse handwheel

Control cabinet

The following are the processable products of Straight ATC CNC Router for your reference

| Model | CK-1325-T |

| XYZ Work Schedule | 1300*2500*200mm(customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, reinforced steel beams |

| Lathe Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Spindle | HQD 9KW high power air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/m |

| Driving Mode | High torque 1.5KW pure servo motor drive * 4 (Z axis uses brake motor) |

| Reducer | Japan Shimpo reducer |

| Tool Change Magazine | 8/12/16 straight tool magazine |

| Table | Double-layer vacuum table with 6 partitions and 24 wells |

| Vacuum Pump | 11KW water ring vacuum pump |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan high precision 30 linear square rail/30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW Double-barrel Bag Vacuum Cleaner |

| Control System | Taiwan LNC cutting machine dedicated control system |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD drawing, CDR, JDpaint, etc. |

| Engraving Instructions | Standard G code |

| Positioning | 4+2 Positioning Cylinder |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Pocessing Speed | 28000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 2900kg |

| Expanded Size | 3900*2100*2100mm |

REVIEWS

Let more people know what you share.