[Function Description]

Fiber laser cutting machine is a new type of cutting machine that uses laser to cut processing materials. It outputs high-energy laser beams and focuses them on the surface of the workpiece, causing the area on the workpiece irradiated by the ultra-fine focal spot to melt and vaporize instantly. The irradiation position of the spot is moved by the CNC mechanical system to achieve automatic cutting. Compared with the bulky gas lasers and solid lasers, it has obvious advantages.

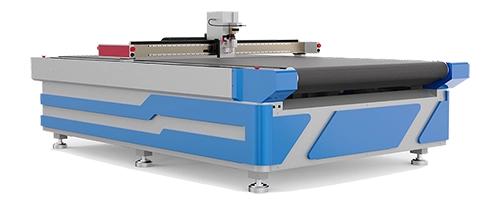

Overview of High Power Fiber Laser Cutter

Fiber laser cutting machine is a new type of cutting machine that uses laser to cut processing materials. It outputs high-energy laser beams and focuses them on the surface of the workpiece, causing the area on the workpiece irradiated by the ultra-fine focal spot to melt and vaporize instantly. The irradiation position of the spot is moved by the CNC mechanical system to achieve automatic cutting. Compared with the bulky gas lasers and solid lasers, it has obvious advantages.

Advantages of High Power Fiber Laser Cutter

Integrated structural design, compact and reasonable overall layout, small footprint, and space saving.

The frame is formed by integral steel mold and die-casting technology, and is precisely processed by large gantry machine tools. After annealing and aging treatment to eliminate internal stress, the geometric accuracy of the machine tool is within 0.03mm.

The machine uses aviation-grade standards to manufacture aluminum alloy gantry brackets and high-strength welding technology. It has high precision and stability, effectively eliminating the vibration generated during high-speed cutting. It adopts the gantry double gear rack and double servo motor transmission structure with high inertia and high torque output, which can greatly and effectively improve your production efficiency.

The crossbeam is made of drawn aluminum profile with precision processing technology, which is light in weight, high in rigidity and good in dynamic performance.

Use RAYCUS laser generator, which is a single-mode continuous fiber laser with sustainable high-power output and high electro-optical conversion efficiency of more than 30%, which can greatly save power consumption.

The RAYTOOLS laser cutting head can quickly perforate and cut metal materials. It can achieve automatic focusing when cutting plates of different thicknesses and materials. It only requires electricity during operation and can achieve a smooth cutting section through auxiliary gas blowing.

Equipped with bus control system, it has super anti-interference ability and excellent stability.

Using the Baichu laser control system and an external wireless handle, it supports advanced functions such as finding the edge of the workpiece, automatic focus control, double shuttle, breakpoint positioning, QR code generation, and residual material segmentation.

The professional laser cutting software has the functions of pattern layout and sharp corner smoothing, which can realize high-speed punching and fast cutting.

Application Scope of High Power Fiber Laser Cutter

Applicable Materials:

Suitable for most metal materials, such as iron, alloy, carbon steel, stainless steel, aluminum plate, brass, copper, etc.

Applicable Industries:

It is widely used in kitchen electrical, sheet metal chassis cabinets, mechanical equipment, electrical equipment, lighting hardware, advertising signs, auto parts, display equipment, elevator manufacturing, various metal products, sheet metal cutting and other industries.

High Power Fiber Laser Cutter Technical Parameters

| Model | CK-1530-F |

| Cutting Area | 1500mm*3000mm (processing size can be customized) |

| Bed Frame/Gantry | High-strength heavy-duty bed support, aviation-grade aluminum alloy gantry |

| Driving Mode | Leadshine servo motor*4 |

| Transmission Mode | Taiwan Hiwin high precision linear square rail, Taiwan Hiwin slider |

| Reducer | Japan Shimpo reducer |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Electrical Parts | Schneider |

| Laser Generator | Raycus CE |

| Laser Head | Raytools |

| Fiber Laser Power | 1500W/2000W/3000W etc. |

| Cooling | S&A Special water chiller for fiber laser generator |

| Control System | FSCUT laser dedicated system |

| Lubrication System | Electric oil injection maintenance system |

| Operating Voltage | AC380V |

| Compatible Software | Artcam, type3, CAD drawing, CDR,AI etc. |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm/1000mm |

| X.Y Axis Max Moving Speed | 100m/min |

| Maximum Acceleration | 1.0G |

| Weight | 4000kg |

| Expanded Size | 5100*2250*2150mm |

Thickness of metal materials that can be cut at different powers

| Power/Material | Q235B(Carbon Steel) | SUS304(Stainless Steel) | Aluminum(6061) | Brass |

| 1500W | 16mm | 8mm | 5mm | 5mm |

| 2000W | 20mm | 10mm | 6mm | 6mm |

| 3000W | 25mm | 10mm | 8mm | 6mm |

| 6000w | 25mm | 20mm | 16mm | 16mm |

Detailed Introduction of High Power Fiber Laser Cutter

Raytools Fiber Laser Cutting Head

The laser cutting head can quickly perforate and cut metal materials. The auto-focus laser cutting head can quickly perforate thick plates and automatically cut plates of different thicknesses and materials.

Highly dustproof: The dustproof level reaches IP65, and the fully enclosed light path has almost zero possibility of lens contamination.

Dynamic focus: The scale can be flexibly adjusted to unify the zero focus position, and no longer worry about adjusting process parameters. The efficient water-cooled focusing mirror and collimating mirror nozzle have built-in cooling function to strongly solve the problem of cutting heating.

Optimized structural design: integrated body design, improved QBH fiber interface is no longer stuck due to leakage and rust.

RAYCUS Laser Generator

High electro-optical conversion efficiency, single-module continuous fiber laser, sustainable high-power output, compact size, high power, light size, excellent beam quality, modular design makes it easier to maintain, maintenance-free operation, wide modulation frequency range, anti-high reflection ability, using the second-generation fiber optic transmission system for cutting, cutting is more stable and precise, the cut plate has a narrower slit, and the advantages are obvious.

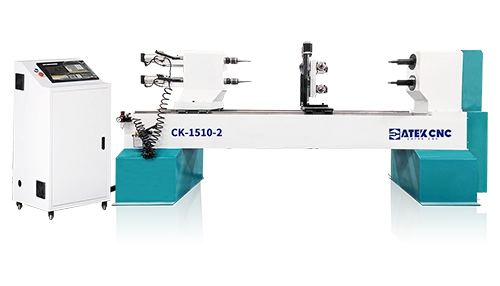

BOCHU laser control system

Using the BOCHU laser control system and an external wireless handle, it supports advanced functions such as finding the edge of the workpiece, automatic focus control, double shuttle, breakpoint positioning, QR code generation, and residual material splitting. It is simple to operate and stable in operation. It can provide fine cutting technology and highlight high-quality cutting effects.

Framework/Platform

The strongest frame of the fiber laser cutting machine. The wall thickness of the rectangular tube is 10mm. The entire bed is processed by gantry milling, which greatly increases the stability of the guide rail and effectively avoids deformation of the bed. The aluminum alloy gantry bracket is manufactured according to aerospace standards. After aging treatment, it is the strongest among all gantries. Aluminum alloy is light in weight, high in strength and does not deform. The frame is formed by using an integral steel mold and die-casting technology. The equipment runs fast and improves processing efficiency. The processing using the sword grid platform is stable and durable.

S & A Chillers

High-precision temperature control system, dual temperature control circulation refrigeration, two independent temperature control systems cool the fiber body and QBH connector at the same time, multiple alarm functions, all-round protection of the laser.

Equipped with water pressure gauge: convenient for observing the water pressure of the water pump;

Additional drainage valve: convenient for drainage;

Universal casters: convenient for movement, equipped with dual-inlet and dual-outlet circulating water interface and water level gauge, more convenient to use.

Control Software

It supports intelligent graphic typesetting, automatic edge-finding cutting and sharp-corner smoothing functions, and can realize high-speed blasting and perforation and high-speed scanning and cutting of array graphics. It has a complete cutting process database. The operator only needs to call the corresponding cutting parameters according to the material and thickness, making the operation more intelligent and convenient.

The following are the processable products of High Power Fiber Laser Cutter

| Model | CK-1530-F |

| Cutting Area | 1500mm*3000mm (processing size can be customized) |

| Bed Frame/Gantry | High-strength heavy-duty bed support, aviation-grade aluminum alloy gantry |

| Driving Mode | Leadshine servo motor*4 |

| Transmission Mode | Taiwan Hiwin high precision linear square rail, Taiwan Hiwin slider |

| Reducer | Japan Shimpo reducer |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Electrical Parts | Schneider |

| Laser Generator | Raycus CE |

| Laser Head | Raytools |

| Fiber Laser Power | 1500W/2000W/3000W etc. |

| Cooling | S&A Special water chiller for fiber laser generator |

| Control System | FSCUT laser dedicated system |

| Lubrication System | Electric oil injection maintenance system |

| Operating Voltage | AC380V |

| Compatible Software | Artcam, type3, CAD drawing, CDR,AI etc. |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm/1000mm |

| X.Y Axis Max Moving Speed | 100m/min |

| Maximum Acceleration | 1.0G |

| Weight | 4000kg |

| Expanded Size | 5100*2250*2150mm |

REVIEWS

Let more people know what you share.

I used a plasma cutting machine before, but it finally broke down last month and is still under repair. I compared it for a long time and finally chose this cutting machine. The fiber laser cutting machine is really much better than the plasma cutting machine! !!