Basic introduction of Pool Cues

Pool cues are divided into English cues and American cues, that is, 3/4 cues and 1/2 cues. The differences between them are weight, diameter of the leather head, section position and manufacturing process, etc.

The raw materials used for English cues are generally maple, and there are also some special materials, such as carbon fiber, carbon, glass fiber, etc.; the raw materials used for American cues are generally ash wood for the front branches (ash wood is lighter and more elastic), and the back branches are made of wood with higher density, such as sandalwood.

Usually, the processing length of 3/4 cue is 1080mm, 1180mm, the back handle length is 430mm, 530mm, and the length of 1/2 cue is 76.5mm.

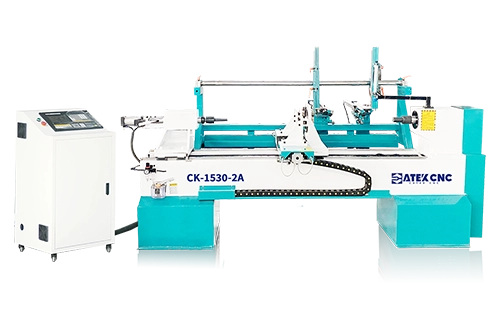

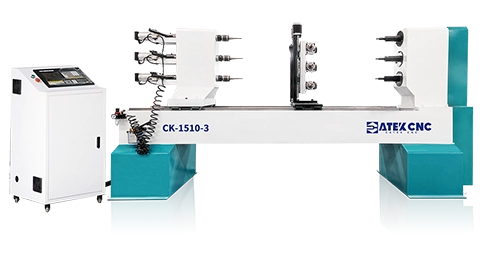

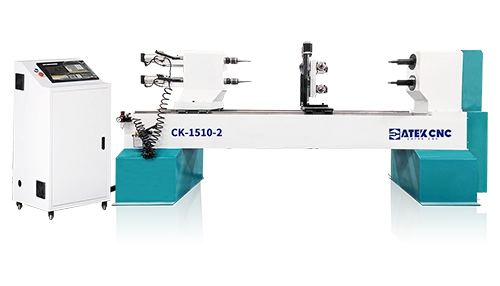

We have machines specially designed for making pool cues,our pool cue CNC lathe has a processing length of 1500mm and a diameter of 100mm, which can be used to process pool cues of any size,the lathe models that can be used to make pool cues are: CK-1510, CK-1510-2, CK-1510-3, CK-1510-A, CK-1510-2A, CK-1510-3A.

Pool Cue processing

processing size through the machine settings, and then process it.

Split, slice, carve and other processes are performed on the processed pool cue to ensure the beauty of the cue.

Punch holes, inlay copper heads, connect screws and deep holes for the back weight.

After the front branch and back handle are connected, grind and polish the whole.

Glue and trim the leather head, modulate the whole cue, and spray paint it.

Pool Cue processing notes

The processing technology of different types of cues will be different. Generally, the most processed ones are English cues and American cues.

Use a high-speed air-cooled spindle of 18,000 rpm to clamp a multi-blade milling cutter to quickly process and cut the material surface. During the processing, the wood rotates at a speed of less than 250 rpm. The lower speed prevents the shaking of too fine materials during the processing, making the surface of the processed wood smoother.

During processing, the material can be processed in layers, and the larger material can be processed in layers and cycles to avoid damage to the tool and material caused by excessive processing in a single operation.

During the processing, the processing speed/material speed/tool speed can be adjusted arbitrarily, and can be adjusted to the appropriate speed according to the length and diameter of the wood.

According to the materials of different lengths/diameters, the appropriate air pressure should be adjusted during processing to avoid too low air pressure, which cannot fix the material, and too high air pressure, which squeezes and deforms the wood.

All CNC woodworking lathes can be equipped with fully automatic vacuum cleaners to ensure that the sawdust in the processing process is completely recycled, which is more environmentally friendly and realizes the secondary use of wood.

CNC woodworking lathe is the most suitable machine for processing pool cues today. It has the fastest processing speed and the highest efficiency among all machines. At the same time, the processing accuracy is also the best. The accuracy of both ends can be controlled within 0.05mm. It is the most suitable choice for pool cue processing factories and personal studios. Whether it is speed, efficiency, or quality, it is the best.

Catekcnc provides you with a full range of pool cue processing solutions, including pool cue taper processing, pool cue punching, pool cue flower arrangement, pool cue engraving, pool cue thread processing, pool cue tenon production, pool cue polishing. We have a full range of processing solutions for you, whether you are a novice or an expert, you can easily master it.

Catekcnc provides solutions for dozens of well-known pool cue factories, has a lot of practical processing experience and theoretical experience, and we have professional engineers to provide you with service 24 hours a day.