Blog list

How to choose a fiber laser cutting machine?

- 10 / 30 / 2024

The core component of a fiber laser cutting machine is the laser. The power of the laser determines the range of the cutting thickness of the equipment. Usually when purchasing a fiber laser cutting machine, the corresponding power size will be matched according to the material to be processed. Faced with the power of multiple specifications on the market, how should we choose the appropriate power?

There are two factors to consider when purchasing a fiber laser cutting machine. First, the power of the equipment can meet your cutting needs; second, whether the price is in line with your budget. The power of the laser cutting machine is one of the core parameters of the equipment. As long as it can meet the needs, there is no need to blindly pursue high power.

The material cut by the fiber laser cutting machine is metal, mainly stainless steel, carbon steel, aluminum plate, brass, etc. The higher the power of the equipment, the thicker the cutting thickness. The power size mainly depends on the laser. In the market, 6000W and above are generally called high power, 3000W-6000W are medium power, and 3000W and below are called low power. Judging from the current market demand, laser cutting machines with a power of 6000W or less can meet the cutting needs of most customers. These devices are also used in large quantities. The higher the power of the equipment, the faster the cutting speed of the same material. However, the important factor in measuring the price of laser cutting machines is the power of the laser.

When cutting thinner metals, low-power equipment is completely sufficient. For example, 3mm stainless steel plates are cut with air using 3000W power equipment. Not only is the cutting speed fast, but the cutting quality is also very fine. It saves costs while not losing accuracy. Therefore, when purchasing a laser cutting machine, you must make a reasonable choice based on your own material, material thickness, etc., and do not blindly pursue high power. Of course, if your processing plates include thick plates and thin plates, and the production capacity demand is large, a high-power laser cutting machine within the price range you can afford is also a better choice. Because by properly adjusting the cutting speed, changing the auxiliary gas, etc., a high-power laser cutting machine can also control the cutting quality very well when cutting thinner plates.

RELATED MODELS

We recommend some related models for you...

Fiber laser marking machine is a new type of marking machine using fiber laser, the machine has the characteristics of small size, good beam quality and maintenance-free.

$880.00~$1,860.00

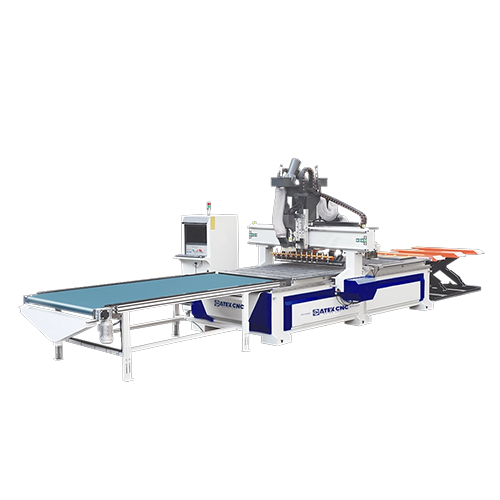

Automatic loading and unloading ATC CNC Router has automatic tool changing function, and also adds full-automatic loading and unloading function, which saves loading and unloading time, greatly improves processing efficiency and saves labor costs.

$9,900.00~$12,000.00

The closed fiber laser marking machine adopts an integrated overall structure and air cooling system, equipped with a sturdy protective shell and open cover protection function, which reduces optical pollution and has the characteristics of high efficiency and low maintenance.