[Function Description]

The CO2 laser cutting and engraving machine is a machine that uses a CO2 laser as a laser source to process materials. The CO2 laser is a gas molecular laser whose working substance is CO2 gas,the auxiliary gases include nitrogen, helium, xenon and hydrogen,it can emit a laser with a wavelength of 10.6 microns.

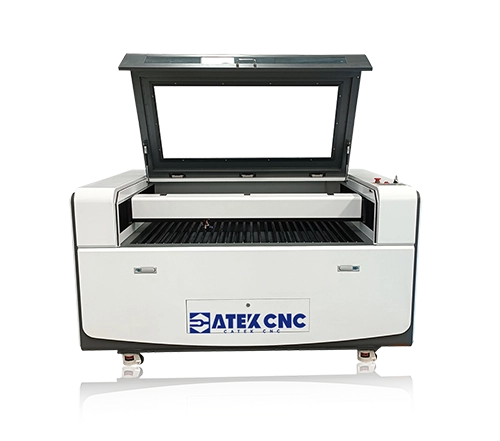

Overview of CO2 Laser Cutting Engraving Machine

The CO2 laser cutting and engraving machine is a machine that uses a CO2 laser as a laser source to process materials. The CO2 laser is a gas molecular laser whose working substance is CO2 gas, the auxiliary gases include nitrogen, helium, xenon and hydrogen,it can emit a laser with a wavelength of 10.6 microns. Through the refraction of several reflectors, the light is transmitted to the laser head, and then the focusing lens installed on the laser head converges the light into a point, thereby gasifying the part to be cut.

The CO2 laser compared to solid-state laser, Although it has obvious disadvantages in processing speed and easy maintenance, its 10.6-micron wavelength laser can process products that solid lasers cannot process, and the cost is lower. You need to choose a suitable machine according to your processing materials and budget.

Advantages of CO2 Laser Cutting Engraving Machine

The 1390 CO2 laser engraving machine has a variety of advantages that make it excel in a variety of applications. First, this laser engraving machine has high precision and high detail capabilities, and can engrave complex patterns and texts, ensuring that each engraving work is accurate and correct. Secondly, it excels in processing a variety of non-metallic materials, including acrylic, wood, glass, plastic, etc., which makes it widely used in industries such as advertising, craft gifts, and furniture.

In addition, the 1390 CO2 laser engraving machine also has fast cutting speed and high cutting efficiency, which can complete a large amount of work in a short time, saving time and cost. Its high electro-optical conversion efficiency and stable performance also ensure the reliability of long-term continuous work. At the same time, the engraving marks of this laser engraving machine are clear and not easy to wear, and the engraving depth is adjustable, which further improves the processing quality. And the 1390 CO2 laser engraving machine is cheap, easy to operate, supports a variety of software formats, such as AutoCAD, CoreIDRAW, etc., and has a wide range of compatibility, which makes the 1390 CO2 laser engraving machine widely praised and loved by customers.

Application Scope of CO2 Laser Cutting Engraving Machine

Applicable Materials:

The machine is mainly used for cutting and engraving various non-metallic materials, such as wood, plexiglass (acrylic), plastic, etc. In addition, it is also suitable for fine engraving work on leather, cloth, ceramics, glass, crystal, rubber, bamboo and wood products, etc.

Applicable Industries:

Industrial applications

Cutting of non-metallic materials such as wood, plexiglass (acrylic), plastics

High-speed, high-volume labeling in the pharmaceutical, tobacco and beverage industries

Material processing, medical use, military weapons, environmental measurement and other fields

Automobile, ship, aircraft, robot manufacturing process

Artwork and sculpture, fabric cutting, architectural model making

Packaging industry

Packaging materials such as glasses, buttons, leather, cloth, ceramics, glass, crystal, etc.

Paper packaging, plastic products, label paper

Advertising and craft industry

Seal making, medals and trophies, gifts and advertising industry

Text and graphic engraving on bamboo boards or wood

High-speed applications in the stone industry

Surface crystal engraving business

Clothing and textile industry

Large-format engraving of clothing, fabrics, carpets, etc. Laser printing and design

Laser Printing and Design

Laser printer creates design or logo, sends to laser engraver for printing

CO2 Laser Cutting Engraving Machine Technical Parameters

| Model | CK-1390-C |

| Work Area | 1300 * 900mm (customizable according to processing requirements) |

| Laser Type | CO2 laser |

| Laser Power | 80W/100W/150W |

| Laser Tube | RECI/YongLi AS6 Laser Tube |

| Laser Head | Auto focus, red light positioning |

| Focusing Lens | US Import II-VI |

| Resolution | ≤0.0125mm |

| Transmission Mode | Taiwan Hiwin high precision linear square rail, Taiwan Hiwin slider |

| Motor | Stepper motor (customizable servo motor) |

| Table | Blade table or honeycomb table |

| Cooling | S&A CW5000 Water Chiller |

| Protective Cover | XY dust cover protection |

| Control System | RDC6442S/ RDC6445G RUIDA |

| Control Software | RDWORKS V8 |

| Supported Formats | JPG,JPEG, PLT, DST, PLT, BMP, DXF, AI |

| Engraving Speed | 1-60000mm/min |

| Cutting Speed | 1-10000mm/min |

| Cutting Thickness | ≤ 25mm (depending on material) |

| Weight | 650kg |

| Expanded Size | 2100mm*1500mm*1200mm |

Detailed Introduction of CO2 Laser Cutting Engraving Machine

Laser tube

RECI CO2 laser tube has a delicate spot and strong penetrating power making it more suitable for long-term use

Laser head

Red dot positioning and auto-focus laser head ensure a safe distance between the material and the lens

Focusing lens

Focusing lens imported from the United States, double size AR coating and high transmittance 99.5%

Table

Honeycomb workbench + blade workbench dual platforms can be used for both cutting and engraving making it more convenient to use

Cooling

S&A cw-5000 water cooler enables the machine to work stably in high temperature environment

The following are the processable products of CO2 Laser Cutting Engraving Machine

Precautions for using The CO2 laser cutting and engraving machine

Safety protection:

When using a laser engraving machine, wear laser goggles to protect your eyes and avoid direct laser exposure to your eyes or skin.

During operation, ensure that the work area is well ventilated to prevent the accumulation of harmful gases.

Be vigilant during operation and do not leave the machine unattended.

Avoid placing the laser engraving machine near flammable and explosive materials, and ensure that the working environment is dry, pollution-free, and vibration-free.

Operation and Maintenance:

Regularly clean the work surface and the residue inside the machine to prevent hidden dangers.

In the case of power failure, regularly clean the machine body with a dry cloth to remove dust and debris.

Check and maintain key components such as laser tubes, guide rails and lenses to ensure their normal operation.

Before the laser engraving machine is powered on for the first time, please confirm that all connecting wires are firmly connected, especially the high-voltage connector of the laser tube, and ensure that the equipment is safely grounded.

Emergency treatment:

In case of emergency, turn off the power immediately.

Make sure that the work area is equipped with a fire extinguisher and check its function regularly.

| Model | CK-1390-C |

| Work Area | 1300 * 900mm (customizable according to processing requirements) |

| Laser Type | CO2 laser |

| Laser Power | 80W/100W/150W |

| Laser Tube | RECI/YongLi AS6 Laser Tube |

| Laser Head | Auto focus, red light positioning |

| Focusing Lens | US Import II-VI |

| Resolution | ≤0.0125mm |

| Transmission Mode | Taiwan Hiwin high precision linear square rail, Taiwan Hiwin slider |

| Motor | Stepper motor (customizable servo motor) |

| Table | Blade table or honeycomb table |

| Cooling | S&A CW5000 Water Chiller |

| Protective Cover | XY dust cover protection |

| Control System | RDC6442S/ RDC6445G RUIDA |

| Control Software | RDWORKS V8 |

| Supported Formats | JPG,JPEG, PLT, DST, PLT, BMP, DXF, AI |

| Engraving Speed | 1-60000mm/min |

| Cutting Speed | 1-10000mm/min |

| Cutting Thickness | ≤ 25mm (depending on material) |

| Weight | 650kg |

| Expanded Size | 2100mm*1500mm*1200mm |

REVIEWS

Let more people know what you share.