Stair railings are a common example of woodworking lathe processing. Relatively simple products only require turning using a turning tool, while complex products require planing, milling, grooving, carving, etc. Depending on the complexity of the product to be processed, a lathe with different functions needs to be selected.The following will recommend corresponding machines for you according to different types of products.

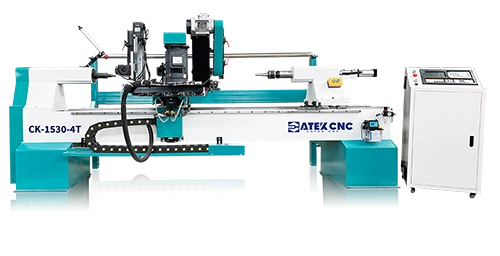

Examples of machining using only a turning tool

Single or double turning tools can be used. A center sleeve can be used during turning to turn slender products.

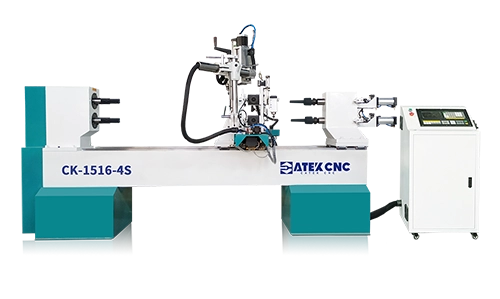

Examples of products that require a spindle for processing

Some stair columns need to be grooved and milled on the surface. At this time, a spindle is needed for secondary processing. After turning is completed, the spindle is used to clamp the milling cutter to groove and mill the product. Some products do not require turning with a turning tool, and only the spindle needs to be used to mill the four sides of the wood.

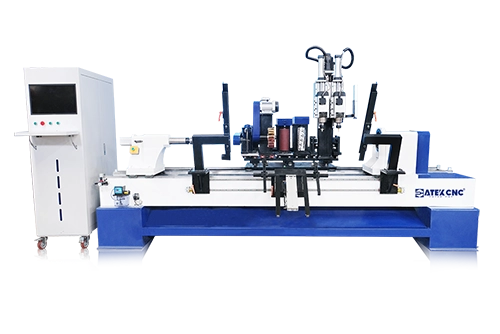

Examples of products that require a planer to process

There are also some stair railings that need to be processed with a planer. The planer can be used to twist, plan, and mill the product. At this time, you can choose to use a planer.

Product polishing

After processing is completed, you can choose to use a grinding wheel to grind and polish the product. Different products require different grinding devices. The grinding wheel can be used to grind the surface of round products, the grinding belt can be used to grind round bars and conical products, and the grinding roller can be used to grind and polish multi-sided and flat products.

How to use CNC woodworking lathe to process stair railings?

When performing simple turning contour processing, we need to draw 2D drawings. We can choose to use cad, cam type software, output dxf format files, import DXF files into the machine through a USB flash drive, and the CNC woodworking lathe control system has a built-in macro program that can automatically convert DXF format drawings into G code. After the tool is proofread, the machine can start automatic processing.

When using a planer for milling, we need to make different drawings according to different products. When processing simple planing surfaces, arc planing surfaces and other products, we can also use dxf format files to start processing. After importing the drawings into the machine, set the parameters of the control system, and the machine can start planing processing. However, when processing four different styles on the four sides, we need to use precision carving or other types of software to make drawings. At this time, the machine needs to read the processed G code for processing.

When using the spindle for simple arc lines or straight line processing, we can also use DXF format drawings to start processing, but there are some relatively complex lines, such as Huiwen, Yunwen, etc., we need to use software such as Jingdiao to output NC format path files for processing, and there are some more complex engraving types, such as using the spindle to process some complex European curved legs, or engraving some people, animals, ornaments and other products, we need to make a 3D model of the product first. After the 3D model is made, we use powermill, artcam and other types of software to convert the 3D model into an NC code file that the machine can recognize, and the machine can read and process it.

The grinding wheel only needs to use the same drawing as the turning shape to start grinding, and no other operations are required.

Some machines can be equipped with automatic feeding function. When using the automatic feeding function, we need to adjust the feeding structure of the machine in advance. After the feeding structure adjustment is completed, we add the automatic feeding code to the drawing of the machine, and the machine can start fully automatic processing. At this time, you only need to manually put the prepared materials into the silo of the machine to start automatic cycle processing.

Different functions can be used to process the appearance shapes of different products. During processing, we need to reasonably match the functions according to the product shape. If you need help, you can contact our engineers at any time.